We’re huge fans of great design, so it’s no surprise that we follow Core77.com, a site dedicated to all things industrial design. Core77 was also one of the 2015 Pro Tool Innovation Awards media sponsors this year and we both got to attend the Festool Germany Media event in Stuttgart earlier this year. This week, Randall Tyner of Core77 published an article under their “Drafting Table Quarterback” series that’s right in our backyard—a look inside a power drill with a breakdown of the two tools to see what really differentiated them.

Inside a Power Drill

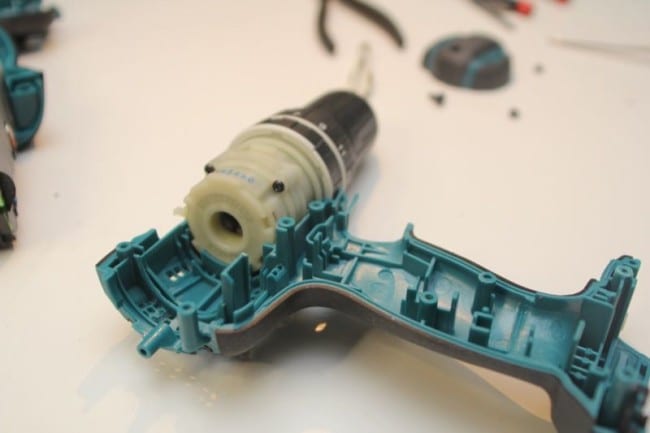

Core77 took apart an entry level Makita and a Ryobi drill and compared them. They looked at the way each of the batteries are made (Ryobi is a post-style Lithium-ion battery while the Makita uses a more common slide pack). It was interesting to see their perspective on the design aspect of having a hollow post—mainly that it was a difficult (but purposeful) design choice which must be continued for reasons of compatibility.

As the article moved on, Core77 described the way the motor and clutch assemblies worked, even as they disassembled the tools and took a closer look. Describing the planetary gears and how the two-speed slider switch works is good reading for anyone interested in understanding how these tools work.

Inside the Plastic Housings

Possibly my favorite part of the piece is where they talk about all that’s involved in tooling the plastic housing components for the drills. They have a real insight into what’s involved and the possible trade-offs and decisions that go into making a particular design with rubber bumpers, accent pieces, ventilation holes, and more. Some areas where I think they may have extrapolated incorrectly had to do what the battery design. Randall presents a case for the difficulty of opening the battery being tied to the companies not wanting users to replace components. We’d say that the reason is more likely to do with the fact that lithium-ion is far more dangerous to work with than NiCd or NiMH. From talking with several manufacturers, you really don’t want to open up these packs and play around if you don’t know what you’re doing.

Overall, this is a fun article and you should definitely check out the whole thing over at Core77.com. While you’re there, check out their other great articles as they are well-written and terribly interesting.