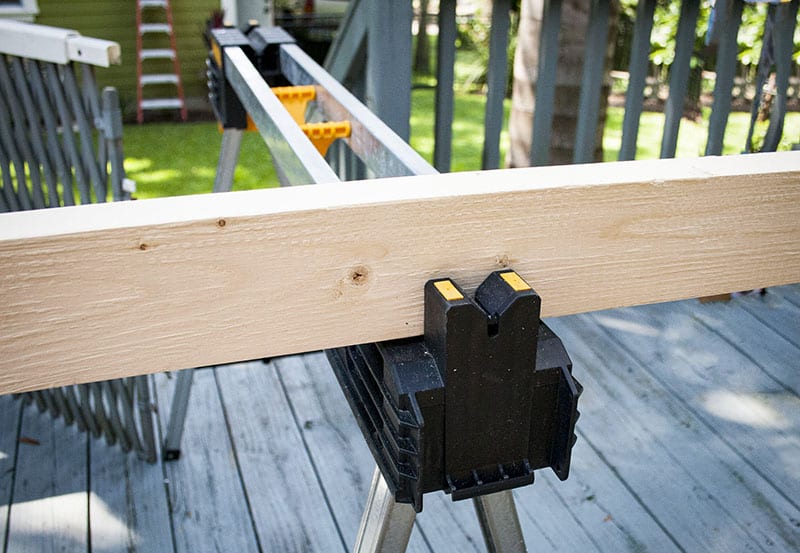

If you are a new homeowner, you probably invested in some of those plastic saw horses for use in your occasional projects. We hope you did because, if you didn’t, you’re probably going to use one of the non-standard ones we list below. Please don’t. They are dangerous on many levels. They are probably not as stable as you think. They tend to be different heights causing you to make imprecise cuts. They may even be parts of your body which is just asking for trouble. Most professionals can make a saw horse out scrap lying around the job site in a few minutes. When they are done with the job, they just break them down and throw them out with the scrap. For the rest of us, it takes just five 2x4x8s to make a basic pair of saw horses (that’s about $10 in materials plus nails), so there is little excuse to not do it right. Add some scrap plywood and 1x material and you can make it more stable. Plus, it’s a great starter project that teaches you a lot. We’ll write up a how-to article on exactly how to build one, but for now – here’s what NOT to do:

1) Milk Crates

Or other boxes. These usually come into play when someone has a miter saw or table saw and needs something on the other end to prop it up. Sure, it isn’t as important as the side with the spinning blade of death but what if the 8 foot 2×4 vibrates off while you’re leaning over to make the cut? Is it really worth the contusion and/or concussion you’re about to have?

2) Truck Tailgates

We see these in use on job sites all the time. Aside from the risk of damage to the truck, you’re looking at a surface that isn’t level and was never made to be used as such. Plus, if your blade hits the tailgate, you’re in for a world of hurt. At best, you’ve scratched the paint and dulled the blade. At worst, you’re looking at a loss of blood and/or limbs from the blade kicking back and burying into your soft pink flesh. Overly descriptive? Good. We’re trying to make an impression here.

3) Outdoor Furniture

We’ve seen many people use their outdoor bistro tables, chairs, and just about anything else in a pinch. Sure they are handy and but they are rarely steady enough, level enough, or even tough enough for the weight you’re about to put on it. Plus, your wife picked those out and you know what she’ll do to you if you cut the arms off one of her teak chairs. Notch a makeshift sawhorse, big deal. Notch that $1500 patio furniture set and you might be sleeping in the workshop for a few days.

4) “Edges”

Stair edges, deck edges, porch edges… anything that someone can use to cantilever a piece of wood over to make a cut. The trouble, of course, is that you also risk cutting into said edge and damaging something that will take far more time, energy, and money to fix. You also have the added problem of never having enough room, so you tend to over-extend your cut and lose any leverage you had – a problem compounded by the fact that you don’t want to cut into your stairs or whatever you’re using.

5) Knee

Now this one is just stupid but we see people doing it all the time. The thing that bothers us is not that people aren’t careful when they do this – in fact, they tend to be extra careful. We just don’t like that there is no room for error. Any problem, any issue with that cut and you are in trouble. The blade binds, the saw kicks, the wood shoots or twists out of your hand…The best result is you drop the saw. The worst… well, we personally know someone who took a circular saw through the thigh. We’ll let you use your imagination on that one.

Building a simple sawhorse isn’t terribly difficult. In fact, it takes about 15 minutes at most and costs only $10 if you do it right. We’ll put out an article shortly that explains exactly how to make one so you can whip a pair together for your next project and save yourself a lot of hassle.