An Interview with Klein Tools About Made in America Tools and International Expansion

Klein Tools invited me to visit their manufacturing headquarters in Mansfield, Texas for a Made in America event. It would include a behind-the-scenes tour of their facilities. We also had an opportunity to meet with some of the people who put the world’s best hand tools in our tool belts. As I packed to leave and thought through what I wanted to learn, I figured this trip was going to be a lot about tools. Don’t get me wrong, I did learn a lot about the process of taking a 20-foot-long steel rod and turning it into a set of Klein All-Purpose Pliers. However, I also learned about a man named Mathias Klein and about the cost of commitment.

Klein Tools Made in America History

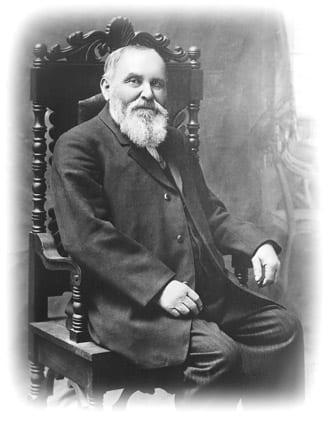

Let me take you back to 1850s Chicago. In a blacksmith’s shop, a German immigrant named Mathias is hammering away at a piece of steel. We’re not really sure what he’s making. It’s not taken form yet. A man comes in the door with a pair of broken pliers. He asks Mathias if it would be possible to fix them. Mathias takes an appraising look, decides that he can forge a new piece for it, and does so.

At a time when people fix what they can rather than simply replace it, the man leaves a happy customer. Not much time passes before he returns. The other side has broken now. Mathias forges the opposite side of what he created earlier and the first set of Klein Pliers has been created. The worker was so thrilled with the quality of Mathias Klein’s work that he told others of this blacksmith. This created a demand for these high-quality pliers.

There at a blacksmith’s shop in 1857 Chicago, America Klein Tools was born.

Most of us are aware of Klein’s reputation for quality. Some of us even know Klein has tools made in America. It’s no accident that Mathias’ insistence on taking the time to make the highest quality tools still resonates throughout the company today. Klein Tools is still owned and managed by the Klein family. The drama of the publicly traded company’s boardroom doesn’t exist here. Where most family businesses only survive to maybe the 3rd generation before being acquired, going under, or sold, Klein now has its 5th and 6th generations of family members on board. The next generation marks the 7th.

The Family Business

What keeps the America-based Klein Tools business in the family? It’s no secret. The Klein family has done do what all good parents do: they teach their children. They teach them about the benefits of creating a quality product. They illustrate the benefits of building a career with Klein Tools. The kids are certainly welcome to make their own decision and walk a different path (and some do). However, time and time again, the descendants of Mathias Klein have chosen to continue his legacy.

Are All Klein Tools Made or Manufactured in the USA?

Klein has always been, and remains, committed to manufacturing their hand tools in the USA. Despite rumors of moving to China, closing plants, or outsourcing jobs elsewhere, they are investing in that “Made in the USA” standard and keeping Americans employed.

Klein Tools does indeed have manufacturing plants in Mexico, Brazil, and Australia. Part of that is logistics. They needed to grow as an international business in an efficient manner. Due to the availability of materials some parts of the manufacturing process simply cannot occur in the USA. Klein Tools views those, not as outsourced jobs that replaced Americans, but rather expansion into new markets.

Klein Tools’ International Operations

I had the chance to chat with John McDevitt, Executive Vice President of Sales and Marketing, about Klein Tools’ international operations and its employees outside of America. In terms of that international expansion, there is a global demand for their products. The result of that demand is that the number of tools produced in America and sold internationally is far greater than what is imported from their foreign plants. Vice President of Marketing, Greg Palese also added that Klein produces 14x more products in the USA than any other country they operate in.

Here’s the kicker for me though: the USA is at a massive trade imbalance (we spend more on imported goods than we sell to other countries), yet Klein brings in more money from their international sales than they send out to support the foreign portion of the manufacturing process. They’re one of the few companies that is helping our trade balance instead of hurting it and the difference is in terms of dollars is incredible.

How Klein Tools Hires and Retains Employees in the USA

If you’re an employer, you know that hiring and training employees is expensive. Klein Tools offers workers in America competitive pay and a solid benefits package. This helps them attract and keep some of the best workers in the industry under their roof. Employees are able to take advantage of health insurance, paid vacation time, a matching 401(k) plan, and higher education help in addition to the profit sharing that each employee automatically gets. The smile that we got from Deborah Jones here is representative of the morale of the employees we saw while touring the facilities.

Klein invests a lot more capital by keeping their operations here and employing so many Americans than it would if it outsourced or simply moved its base of operations outside the USA. Yet by doing so, they keep Mathias’ legacy alive and keep the production line vertical. From selecting the steel that is mined here in the US through every step of manufacturing and distribution, Klein has control of each part of the process. Every tool is in the hands of an employee for inspection before it can be packed and shipped off to its final destination. This vertical integration and capital investment means that every tool meets Klein’s expectation that they are producing the highest quality hand tools in the world.

Final Thoughts

Klein seems to place lots of quality in their tools. Their tools provide innovative ways to make the job of a tradesman easier. However, Klein Tools also represents more than a tool company. They’re also American dreamers and idealists who still believe the highest quality is the only quality and that loyalty to the country that accepted a German immigrant over 150 years ago is simply part of who they are.