It’s been several years since I used my first oscillating multi-tool, but I still remember thinking that it might become one of the most useful tools in my shop. It doesn’t happen as often as I’d like, but this time, I was right. The general design is small, lightweight, and so versatile that it allowed me to sand; saw metal, wood, and drywall; make large holes or the finest of plunge cuts; remove grout, cut trim for new flooring, cut old nails and screws off flush, and that’s just a start of what I use something like the Ridgid JobMax 12V Multi-tool for.

The time came to replace my original multi-tool (a moment of silence, please) and one of my options was the Ridgid JobMax 12V Multi-Tool Kit. It’s no surprise that Ridgid has innovated the heck out of this already incredibly handy tool. I’m using the 12V model, but it’s important to note that this tool is only part of a modular system that includes a choice of power bases – pneumatic, corded, 12V lithium-ion, or 18V lithium-ion. Each base can attach to several interchangeable heads that include a multi-tool head (included), a reciprocating saw, a jigsaw, a right angle drill/driver, right angle impact driver, an auto-hammer, a ratchet, and a rotary head.

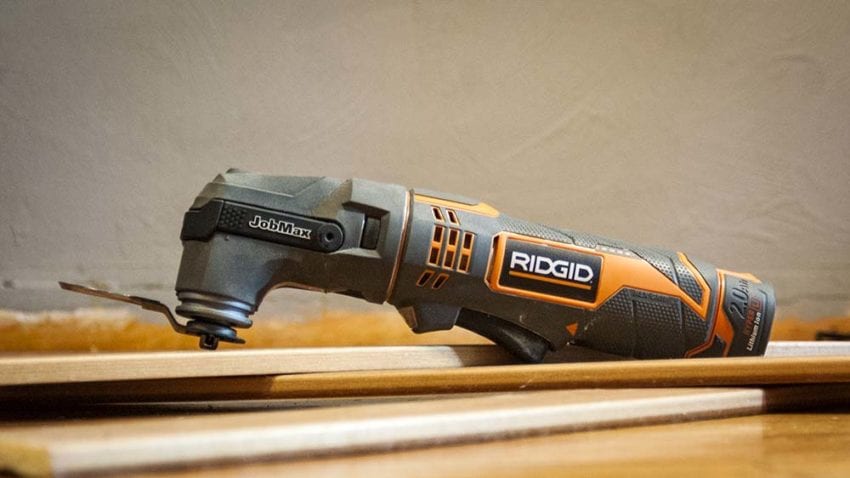

Ridgid 12V JobMax Features

By depressing the two spring latches on the power base that holds the head, you can remove or rotate the head into one of four positions around the power base. The accessories (blades, sanding pads, etc.) can be in any one of twelve positions when attached to the head. The best part – there’s no hex key required to change the accessories.

When I realized there was no more hex bolt to worry about, I think I heard a chorus of angels in the distance. In the old days, when you wanted to change an accessory, you had to use a hex key to remove the threaded bolt holding it to the head. But where did I put my hex key? Nobody knows the answer to that, but I’ve got a drawer full of them and I can’t ever seem to find the one that fits. Thanks, Ikea.

Ridgid accomplishes this tool-free magic by the use of a sliding lever built into the head. Slide it out, pull it back, and the accessory clamp releases your chosen implement of material removal.

The Ridgid JobMax 12V Multi-Tool’s power base has a two-finger variable speed trigger. Just below the trigger is the forward/reverse toggle for use with the drill/driver heads. Other notable features include a bright LED light that illuminates the workspace, an on-board fuel gauge, an adapter to use other brands’ accessories (I’ve used the adapter as part of the review), and a lifetime warranty with free batteries, parts, and service with product registration. I’d say all of this is quite for less than $100.

Performance

So how did the Ridgid JobMax 12V Multi-Tool work? In a word: Excellent.

Part of my house has a leaky, soon-to-be-replaced flat roof which has caused me considerable angst each time my own repairs failed to meet professional standards. Hey, I’m good at a lot of things, but roofing is not my calling. I’m bringing in the Pros for the roof this time. In the meantime, I had some damaged drywall on the ceiling and some damaged furring strips to remove on the inside.

I cut into the drywall using the half-circle wood/drywall accessory and drew the multi-tool through the drywall with ease. You can certainly use two hands to steady the multi-tool, but a big advantage of the design and weight of the 12V model is the easy one-handed operation.

Just to prove that it can be done, I swapped the Ridgid drywall/wood accessory for the adapter and a competitor’s drywall/wood accessory. It’s an easy change and, although the old accessory was a little past its prime, it still got the job done. I swapped then for the rectangular wood blade made for plunge cutting and cut through the furring strips easily. I realized quickly that having the reciprocating saw head for that particular part of the job would have been very helpful (maybe in the next review).

Finally, I attached the sanding pad accessory and an 80 grit pad and set it to work on a rough sheet of plywood. I rounded the edges and smoothed the surface of the sheet with ease – it was so easy, in fact, that I took my own photos with my free hand. I realized I had more control over the tool than I would have with an orbital sander and the Ridgid JobMax 12V Multi-Tool is certainly more nimble (and requires fewer hands) than a belt sander.

One safety issue I would emphasize – and it is including in the user’s manual instructions and warnings – is to remember to remove the battery when changing accessories on the Ridgid JobMax 12V Multi-Tool. This is really nothing but wisdom: “Hey, remove the power when your fingers will be near moving metal teeth!” It still bears repeating with the multi-tool because your hand will necessarily be very close to metal teeth when pulling back the sliding lever to loosen the accessory clamp – while your other hand will be by the trigger that would move those teeth if the tool is powered.

Conclusions

Versatility is the name of the game with the Ridgid JobMax system. It’s obvious with the range of heads that are available, but also with 4 different power bases to choose from. Going with the Ridgid JobMax 12V Multi-Tool Kit is a great solution for the pro-minded homeowner and occasional Pro user (heavy Pro users will want to go with the 18V model). Run time is limited compared to the 18V kit, but there’s still plenty of power to get the job done. The real benefit of this kit is in the lightweight ergonomics of the tool.

Overall, it seems like Ridgid thought of just about everything for this multi-tool. I was already sold on the usefulness of the general design, but the innovations Ridgid has made – the tool-free accessory change, the LED light, the variable speed trigger – will only make the JobMax 12V Multi-Tool Kit that much more valuable in your shop, around your home, and on the jobsite.

Ridgid JobMax 12V Multi-Tool Kit Key Features

- Tool-free multi-tool head changes

- Variable speed trigger

- 4° of oscillation

- Compact head profile

- Battery fuel gauge

- Tool-free quick connect interface with 4 positions

- LED light

- Universal adapter

- Hex grip overmold

Ridgid JobMax 12V Multi-Tool Kit Specifications

- Model: Ridgid R82236

- Power Source: Ridgid 12V battery

- No Load Speed: 0 – 20,000 SPM

- Adapter Style: Universal

- Price: $99.97

- Warranty: Lifetime Service Agreement with Registration