If you ever take a look through the features of a product on Makita’s website, brushless motors get lots of mention. We interviewed the company about what actually makes Makita brushless motors different from the competition.

During the process, I had the fortunate opportunity to chat with Carlos Quintana. Carlos is the Senior Product Manager for Makita Cordless Tools—and he provided some pretty clear answers.

10-Second Summary

- The motors are chosen specifically to match the design & purpose of the tool

- Outer rotor designs allow for speed and power gains in some OPE and heavier duty tools

- Magnets matter

- The Makita LXT line uses at least 5 different brushless motors

Designing Makita Brushless Motors with a Purpose

When Makita talks about purpose-built motors, they mean they specifically select the motor to match the tool. Now, you can order any size motor you want from China and plop it in a tool. It will run. Makita looks at not only what the tool is, but also how it functions. They also consider the accessories it will use and the materials being cut, drilled, and/or fastened.

Makita impact drivers present a great case-in-point. The Makita XDT16 has a very compact tip-to-tail design. It’s actually one of the best impact drivers we’ve tested to-date—and certainly one of the most compact. Contrast that with the Makita Sub-Compact Impact Driver. It features a longer but narrower design.

Both impact drivers use the same battery. The design of the Sub-Compact model, however, combines the light weight and power of a 12V tool with a head profile that fits into narrow spaces. For this reason, they selected a longer, narrower brushless motor design.

Other tools, like the 18V X2 AWS Rotary Hammer, compete specifically with—and even outperform—corded models. Makita went with an 80mm inner rotor design on these tools. It delivered a 1-9/16 in. SDS-Max rotary hammer that drills faster than the nearly identical corded model on which it’s built.

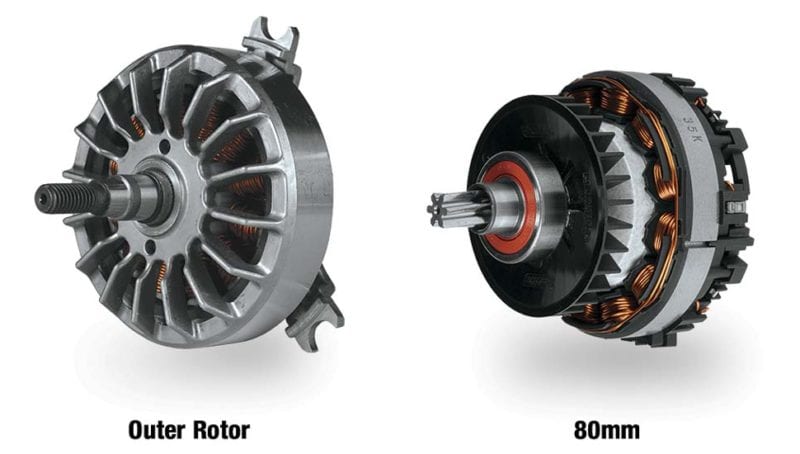

Makita Brushless Inner Rotor vs Outer Rotor Motors

Makita uses an 80mm outer rotor brushless motor in both their 18V X2 chainsaws and string trimmers. The compact design makes them narrower than an inner rotor motor. It also weighs less and lets Makita deliver higher speed and torque in their direct-drive systems.

While there are few downsides to an outer-rotor brushless motor, inner-rotor designs give you more versatility. You can vary both the length and diameter of the tool. You’ll find an 80mm inner rotor brushless motor in high-performance tools like Makita’s cordless SDS-Max rotary hammer. A 54mm inner-rotor design drives their premium line. Finally, 44mm and 38mm inner-rotor motors expand the compact and Sub-Compact models.

In short, Makita has a variety of options to get the size, shape, and performance dialed in the way the product team envisions it.

Makita Brushless Motor Magnets

What’s the difference between a cheap tool and a premium one?

Makita gives us the example of the magnets in their 80mm inner rotor brushless motor. This Makita brushless motor uses 8 magnets instead of the more common 4.

From there, they shape and embed the magnets perfectly before epoxying them in place to ensure they won’t go anywhere during use. Just to be sure, this and all of their brushless motors go through testing up to 30,000 RPM.

More than Just a Motor

Right now, the Makita LXT line uses at least 5 different BL motors to power their brushless tools. That’s not the whole story, though.

Those brushless motors need a power source—Makita 18V LXT battery packs. With that 18V battery platform, Makita gives you four levels of cordless tools to work with. Sub-compact replaces the need for 12V. The 18V X2 line eliminates the need to jump up to a 36V battery pack. In between are compact and premium 18V tools that give you a complete line on one battery system.

The controller sits between the motor and battery in every brushless tool. That’s where things get really specific. Each Makita brushless tool model has its own electronic controller that customizes the energy curve between the battery and motor. Even though you have 5 motors to choose from, each one performs differently from one tool to the next because the product team can tell it exactly how to run.

The Bottom Line

The next time you hear one of the folks from Makita talking about a Makita purpose-built brushless motor, realize it’s more than just marketing jargon. Their team of product managers and engineers put a lot of effort into getting the perfect motor in the brushless tools you’re using and dialing in the controls to make sure you enjoy the experience of using a premium cordless tool.