For several years now, we’ve been seeing brushless motors begin to dominate the professional tool industry’s drive in cordless tools. That’s great, but what’s the big deal? As long as I can still drive that timber screw, does it really matter? Well, yes it does. Significant differences and implications exist when dealing with brushed vs brushless motors.

Table of Contents

How a Brushed DC Motor Works

Before we dive into brushed vs brushless motors with both feet, let’s look at the basics of how a DC motor actually works. When it comes to driving a motor, it’s all about magnets. Oppositely charged magnets attract each other. The basic idea in a DC motor is to keep the opposite charge of the rotating piece (the rotor) attracting the non-moving magnets (the stator) in front of it so there’s a constant pull forward. Think of it like keeping a Boston creme doughnut on a stick in front of you while running—you’re going to keep trying to catch it!

But how do you keep that doughnut moving? The complex solution starts with a set of magnets that hold a permanent charge (permanent magnets). A set of electromagnets change their charge (reversing polarity) while the rotation occurs. This creates a persistent situation where an oppositely charged permanent magnet exists for it to move toward. In addition, the “like” charge that the electromagnetic coil experiences when it changes pushes the coil away. When we look at brushed vs. brushless motors, just how that electromagnet changes polarity makes all the difference.

Looking Inside a Brushed Motor

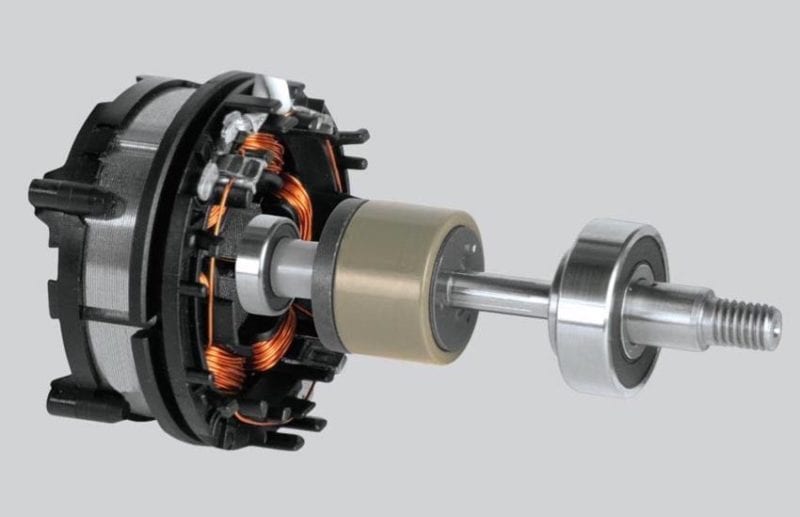

Inside a brushed motor, you find four basic parts. You have permanent magnets, an armature, commutator rings, and brushes. The static permanent magnets make up the outside of the mechanism and don’t move. We call this the stator. One magnet holds a positive charge and the other holds a negative charge. This creates a permanent magnetic field.

The armature is a coil or series of coils that become electromagnets when you apply power. This part also spins (we call it the rotor). Typically, the rotor coils use copper, though sometimes you find aluminum.

The commutator rings are fixed to the armature coil in two (2-pole configuration), four (4-pole configuration), or more pieces. They spin with the armature. Finally, the carbon brushes stay in place and deliver the electrical charge to flow to each piece of the commutator.

It’s All in the Armature

Once you power the armature, the charged coil pulls toward its oppositely charged permanent magnet. As the commutator ring above it also spins, it moves from a connection with one carbon brush to the next. When it reaches the next brush, it receives a polarity reversal. Now it wants to move toward the other permanent magnet while being simultaneously repulsed by the like charge. The commutator arrives just in time to form a connection with the positive brush and follows around to the negative permanent magnet. Brushes live in pairs, so a positive coil will pull toward the negative magnet while a negative coil pulls toward the positive magnet at the same time.

It’s like I’m the armature coil chasing that Boston creme doughnut. I get close, but then change my mind and go after a healthier smoothie (my polarity, or desire, changed). After all, the doughnut is full of calories and fat. Now I chase the smoothie while being pushed away from the Boston Creme. When I get there, I realize how much more delicious that doughnut will be over a smoothie. For as long as the trigger’s pulled, I change my mind every time I get to the next brush while chasing the object of my affection frantically in a circle. It’s the ultimate in ADHD put to good use. Plus, there are two of us in there, so the Boston creme doughnut and smoothie are always being chased passionately, but indecisively, by one of us.

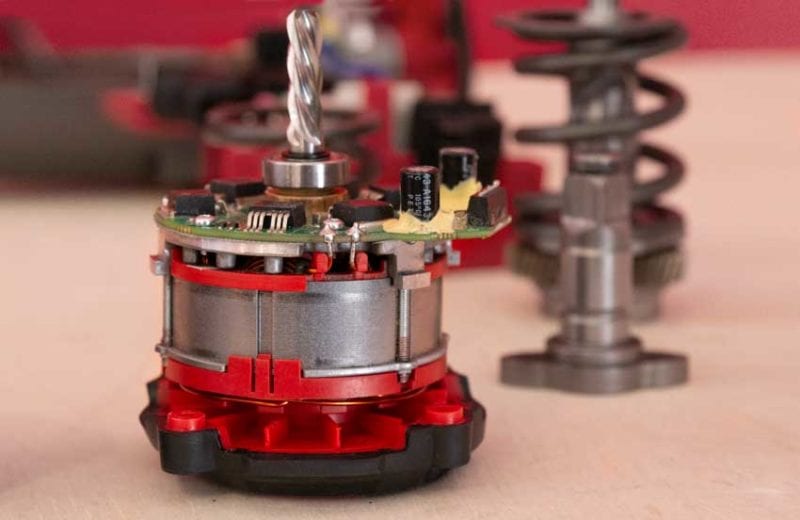

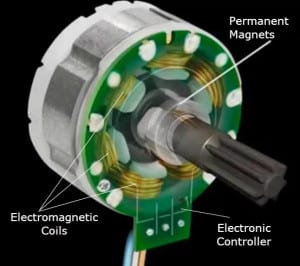

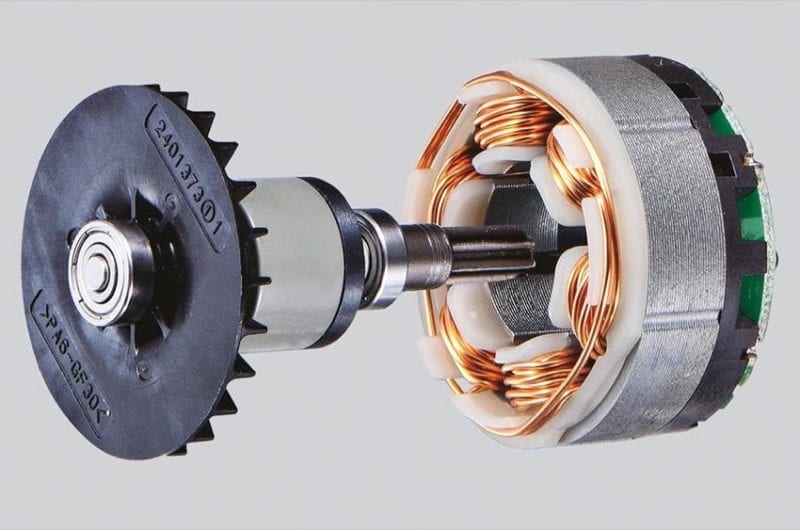

Inside of a Brushless Motor

In a brushless motor, you lose the commutator and brushes while gaining an electronic controller. Now the permanent magnets act as the rotor and rotate around on the inside while the stator is made up of the fixed electromagnetic coils now on the outside. The controller powers each coil according to what charge it needs to attract the permanent magnet.

In addition to moving the charge around electronically, the controller can also provide a like charge to oppose the permanent magnet. Since like charges oppose each other, this pushes the permanent magnet. Now the rotor is moving thanks to a pull and a push.

The permanent magnets are moving in this case, so now they are my running partner and me. We aren’t changing our minds about what we want anymore. Instead, we know that I want the Boston creme doughnut and my partner wants the smoothie.

The electronic controller keeps our respective breakfast delights moving in front of us and we’re always chasing the same thing. The controller also puts what we don’t want right behind to offer a push.

The Cost of Brushed vs Brushless DC Motors

The brushed DC motor is relatively simple and the parts to make it are inexpensive (though copper isn’t getting any cheaper). Because brushless motors require that electronic communicator, you’re essentially starting to build a computer inside your cordless tool. This is what drives the cost of brushless motors up.

Brushed vs Brushless Motor Efficiency

Brushless motors offer several advantages over brushed motors thanks to the design. Much of it has to do with the loss of brushes and commutator. Since the brush is required to be in contact with the commutator to deliver a charge, it also causes friction. Friction reduces the speed that can be achieved along with building up heat. It’s like riding your bike with the brake lightly applied. Given the same amount of effort from your legs, you’ll be slower. Conversely, if you want to maintain the speed, it will take more energy from your legs. You’ll also heat up your rims from the frictional heat. This means that, compared to brushed motors, brushless motors run cooler. That gives them more efficiency, so they convert more electricity into power.

Carbon brushes also wear down over time. It’s what causes a spark inside some tools. In order to keep the tool running, the brushes have to be replaced once in a while. Brushless motors don’t require that maintenance.

While brushless motors require an electronic controller, the rotor/stator combination is more compact. That leads to the opportunity for lighter weight and a more compact size. That’s why we see so many tools like the Makita XDT16 impact driver have a super-compact design and plenty of power.

Brushed vs Brushless Motor Torque

There seems to be a misconception around brushless motors and torque. The brushed or brushless motor design itself doesn’t really indicate the amount of torque. For example, the first Milwaukee M18 FUEL hammer drill had less real-world torque than the brushed model that preceded it.

Eventually, however, manufacturers realized something very critical. The electronics used in brushless motors can supply those motors with more power when needed.

Because brushless motors now utilize advanced electronic controls, they can sense when they begin to slow down under load. So long as the battery and motor are within temperature specs, the brushless motor electronics can ask for, and receive, more current from the battery pack. This lets tools like brushless drills and saws maintain more speed under load. This makes them faster. Often much faster. Some examples of this include Milwaukee RedLink Plus, Makita LXT Advantage, and DeWalt Perform and Protect.

These technologies seamlessly blend the tool’s motor, battery, and electronics into a cohesive system to achieve the best-possible performance and runtime.

Deeper Dive Into BLDC Motor Technology

Commutation—varying the polarity of the charge—starts the brushless motor and keeps it turning. Next, you need to control both speed and torque. Varying the voltage to the stator of a BLDC motor controls the speed. Modulating the voltage at higher frequencies lets you control the motor speed to an even greater degree.

To control torque, you can reduce the stator voltage when the motor’s torque load rises above certain levels. Of course, this introduces the key need: motor monitoring and sensors.

Hall effect sensors provide an inexpensive way to detect the position of the rotor. They can also detect speed by timing when and how often the sensors switch.

Editor’s Note: Check out our What is a Sensor Free Brushless Motor article for how advanced BLDC motor tech is changing power tools.

The Final Verdict

The combination of these benefits has another effect—a longer life. While the warranty is typically the same for brushed vs brushless motors (and tools) within a brand, you can expect to get a longer life out of the brushless models. This can often be years beyond the warranty.

Remember what I said about the electronic controller essentially building a computer in your tool? The brushless motor is also responsible for the breakthrough of smart tools hitting the industry. Milwaukee One-Key technology wouldn’t work if not for the brushless motor’s dependence on electronic communications.