We’re not sure who or what this tool will ultimately target, but Alec Rivers, a Ph.D. student at MIT, developed a self-correcting router that only needs to be loosely guided by hand and can perform intricate cuts to a preset path. The system is actually relatively compact and uses computers to guide the router along its path. All you need to do is keep the mechanism in the ballpark. This really begs the question: when will this be available for vehicles? But I digress…

Shaper Origin Began as an Automatic Self-Guiding Router

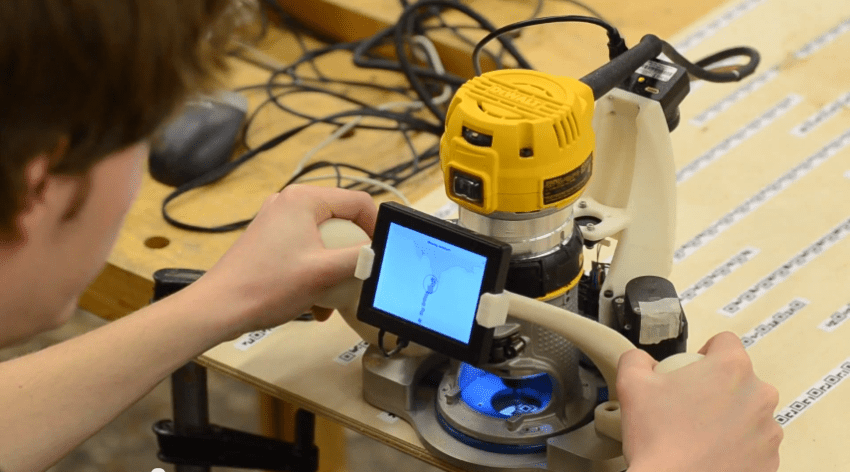

The system uses an integrated camera that shows the path to be cut, and there are motors that “float” the mechanism to keep it perfectly aligned to the cutting path. Rivers’ call is a “tool GPS,” which is a pretty good way of describing it.

What will likely NOT appeal to professional woodworkers is the fact that, instead of carefully looking at the wood you are cutting, you are instead to focus on the LCD display, making sure you are staying within the limits of the system’s tolerance for correction (represented by a circle/target at the center of the screen). If you keep the center dot on the cutting path, the system does the rest – and you can literally see in the video, the router moving within the mechanism, keeping itself perfectly on the complex cutting path (in this case, a map of the United States).

The current clearance for the automatic self-guiding router – the tolerance – is 1/4″. That’s pretty generous. Stay within that tolerance, and the motors will direct the bit to where they need to be. Now, where this seems to get a bit gray (to us) is how this intersects with the idea of an inexpensive CNC machine. Using a router to round over or bevel the edge of a piece of wood is one thing, but meticulously carving out a pattern begins to enter the specialty realm of design, including craftwork, sign-making, and more.

The Appeal of the Shaper Origin Router

The traditional woodworker is unlikely to latch onto a design like this and get excited. One, because it actually involves more work (setting up the design on the computer), and two, because it removes the art from the equation and replaces it with a rigid, sterile pattern cut. The video uses something that looks like a DeWalt DWP611PK compact router to show off the system.

With that said, we can think of numerous uses for an automatic self-guiding router in a commercial shop where repetitive cutting is crucial to output and productivity. The difference is, of course, that while the system provides exceptional control, you still have to babysit it – unlike a programmable CNC machine. And that’s where we simply have to wait and see where this goes. The desired application and target market will determine a lot with respect to how successful this tool will be.

One area where it is perfectly suited is in applications where the system needs to perform a critical cut or design in a location that is “off-site.” A CNC machine is hardly portable, and hand-cutting a precision cut into a once-and-done location may be something that would truly benefit from a system like this.