Roofing nailers come in many sizes and shapes. Bosch’s Coil Roofing Nailer RN175 provides several advantages that we wanted to test out in the field. By evaluating it in practical use we hoped to see whether this relative newcomer could compete in a market that has been dominated by a relatively small number of stand-out manufacturers for a long time.

The attraction of Bosch’s new line of pneumatic tools includes the advanced technology they use in order to eliminate a lot of the volume typically required in order to reset the tool during each firing of the pneumatic piston. In the case of the RN175, we found that while the tool absolutely has less girth than many competing products, the tool still overall has an equivalent heft and bulk to many of its competitors.

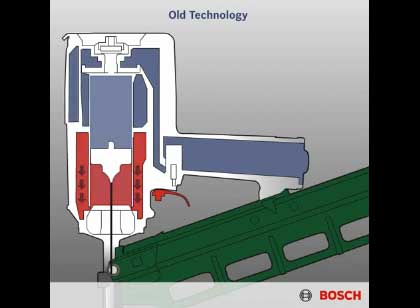

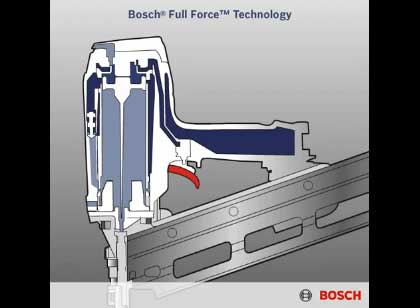

Bosch Full Force Technology

According to Bosch, the company has been working, in some fashion or another, on the Full Force design for around 4 years. The Full Force technology uses a patented air chamber design that eliminates the need to use some of the drawn air to recycle the driver to the start position. Basically, it sends a second, smaller, burst of air through the gun that resets the driver – removing the need for a surrounding chamber to store air. The result is a 20 percent space savings (mostly in girth) and 10 percent power boost over comparable tools. The power-to-size ratio is actually quite impressive – and anyone who picks up the nailers sees this right away.

Bosch Coil Roofing Nailer RN175 Build Quality

The first thing we noted about the Bosch Coil Roofing Nailer is that it is an attractive and durable looking tool. Its frame is made from cast aluminum and looks to have an almost beaded finish. The colors are a flat metallic silver with the expected Bosch Blue provided on the rear of the tool and the coil nailer cover. The mechanisms are all black and everything looks to be very well made, both in terms of its function and durability.

Bosch also strategically places protective rubber overmold on the sides such that the nailer can handle the wear and tear of typical roofing jobsite use. What they appeared to have done is simply throw the tool down on a roof over and over again and noted where the typical wear patterns occurred. In both locations, they placed both metal protective plates as well as thick, protective, overmold pads. It’s genius and in our use, they did indeed seem to be placed in exactly the places you’d need to protect the tool.

Loading Coil Nails

Loading nails was quite easy, and Bosch opted to use a single swing arm method for opening up the protective cover. We actually preferred this to the double-latch method employed by manufacturers like Hitachi and Senco. Swinging the cover open is accomplished by pushing on the latch, typically with your left hand, and flipping open the cover. You can then place the new coil of nails into the height-adjustable spool and position the first nail onto the securing magnet to hold it in place.

After using the tool for an entire roofing project, we discovered in a short amount of time that loading the tool one-handed was made very easy by the nature of the mechanism. It was also very fast, much more so than many competing tools we’d used.

Replaceable Trigger

Firing nails is made possible by the trigger mechanism, which we liked in its default bump mode. What we found odd, however, was that Bosch opted to use a replaceable trigger mechanism, rather than the simple tool-less trigger mode adjustment present in its Framing Hammers and Finish Nailers. While bump mode was the default, and presumably the most common use for roofing applications, we wondered why they didn’t opt for the more advanced and flexible trigger mechanism.

To re-adjust the tool for use as a siding or hardy-plank installation tool you need to perform a trigger change in the field. This is difficult to do without losing either a part, a tool, or even the trigger itself. We always opt for flexibility, and a trigger mode trumps, in terms of convenience, a physical swap-out every time.

Depth Adjustment Control

The tool has an innovative depth adjustment control. This is made possible by altering the front of the tool’s depth to the workpiece by turning or rolling a red metallic control gauge located just behind the firing point on the left side. An example of how this became incredibly useful was when we utilized two different manufacturer’s pneumatic coil roofing nailers from the same 4-gallon compressor. The result was that the Bosch drove our 1-1/4″ roofing nails with no problem, perfectly flush while the other manufacturer’s tool wouldn’t consistently drive our nails all the way in.

Since the other tool had no depth adjustment, our solution was to simply raise the output PSI from the compressor and then simply back off the depth setting of the Bosch Coil Roofing Nailer. In this way, both tools drove nails to the perfect depth. Had we not had this option we would have either been doing a lot of hammering or would have needed to bring out another compressor.

Using the Bosch Coil Roofing Nailer in the Field

We took Bosch’s new Coil Roofing Nailer to a jobsite that involved installing about 30 squares of architectural shingles on the roof of a 1920’s style home with several valleys and lots of interesting detail. We’re in the South and so utilized a high-wind 6-nail nailing pattern. The bottom line is that we fired a lot of nails into this roof. The nailer as also used alongside a competitor’s product, a Senco RoofPro 450 and we passed the tool around to no less than four different professionals, each of which formed their own opinions about the tool.

Specific Highlights

There were several consistent comments that came up during the course of the project that we felt important to note here:

- Power and Consistency

It became clear that the Bosch Coil Roofing Nailer was a consistent performer. In terms of using it for our project it was a simple decision to make the Bosch our go-to tool. The RN175 nailer handled our full-length 1-1/4″ nails, whereas our other nailer was loaded with the shorter 3/4″ nails designed for use on the exposed rafter edges to keep to the visual appeal desired by the local government’s historical society.

- Carefree Tool Protection

There were two really good aspects of the select rubber and metal overmold provided on the Bosch Coil Roofing Nailer. For one, we could just about drop the tool anywhere on the shingled roof and not have to worry about the tool getting too roughed up or suffering damage. The other positive aspect was that the side molding gave the tool additional friction. We had to go chasing after our competitor’s tool on more than one occasion as it slid down the roof towards the edge. The Bosch had more “sticking” power on the sloped roof deck.

- Easy Coil Nail Changes

It was remarkably easy to change the nails on the Bosch Nailer. Instead of a dual hinged compartment, we simply flipped open the nail canister cover and loaded the tools. This was simple to do even when we had the tool in-hand and were standing up on the roof.

- No Dry Firing, Every Nail Used

It was refreshing to know that the Bosch fired every last nail. And when it got to the end of a coil, it simply stopped firing. This served two very important purposes – one, it protected the material, principally, the shingles from damage from dry-firing. Secondly, it alerted us immediately of the need to add a new coil of nails. Using the competition, it was easy to fire one or two blanks before realizing you were out. That translates into wasted time. Over the course of an entire roofing project, this likely saved us countless minutes.

Conclusions & Recommendations

Bosch doesn’t give professionals and consumers much to dislike about their Coil Roofing Nailer. It’s compact, easy to load, easy to use, and most importantly – consistent. With this tool you don’t get mixed results, your nails hit flush every time. It’s also easy to adjust the tool so that it drives the nail perfectly – and this without having to get down from the roof and adjust the air compressor.

The nailer is well-protected and we loved the fact that it loaded quickly and easily, even one-handed. We believe the Bosch RN175 Coil Roofing Nailer excels in performance. More, it does this excellent work in a very small package. We also feel it presents great value. We can recommend it with enthusiasm to professionals and contractors who want a tool they can set and forget and expect to use for a long time.