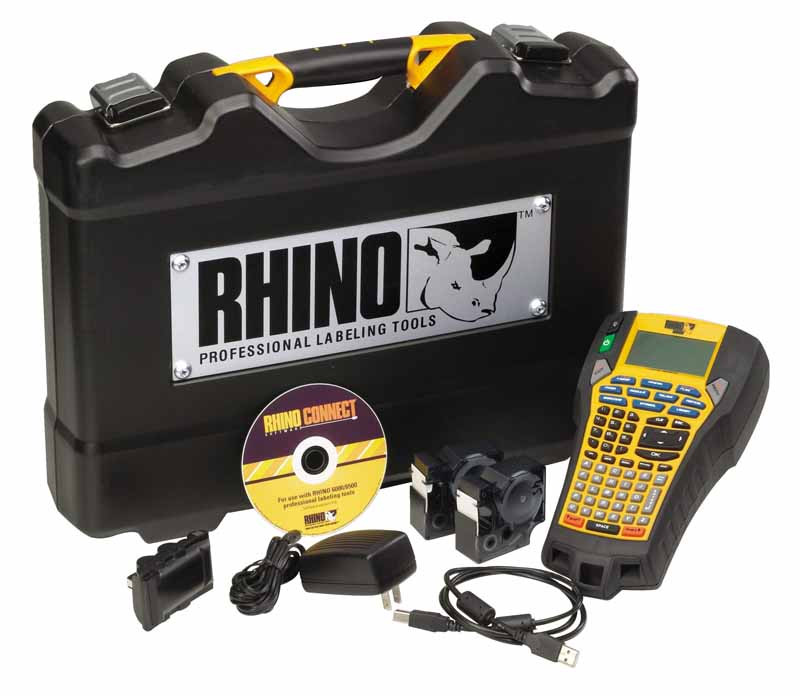

Are you an electrician, plumber, or just someone who needs to print out good labels as part of their daily job? If so, I’d hope that by now you’ve heard of Dymo’s Rhino brand of label printers. They are sort of an industry standard in my circles and the company just released two new products in the past year that simplify and enhance what was already a pretty impressive line of labeling tools. Dymo has a substantial collection of products which mainly target the journeyman and professional user. The brand is also known for ensuring they have a variety of labels that will work in almost any environment. They have entry-level nylon tape, colored vinyl tape cartridges and even permanent polyester labels that can handle the elements and bumpy application surfaces. Dymo has listened to the desires of electricians, A/V installers and professional journeymen and the Dymo Rhino 6000 label printer seems to be a customizable solution that just works.

Dymo Rhino 6000 Label Printer Features

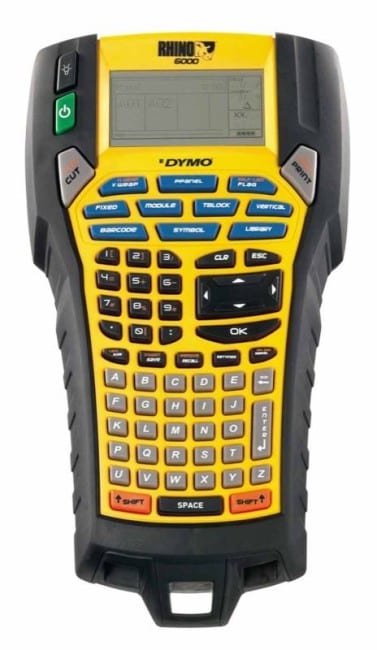

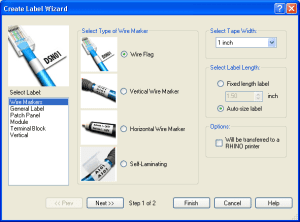

The former professional label leader, the Dymo Rhino 5000 label printer, had only five small label style buttons (WRAP, FIXED, PPANEL, TBLOCK and VERT). Everything else had to be accessed using finger gymnastics and internal adjustments. The revised label printers make it simpler to get where you need to go, and the larger, more detailed LCD screen gives yo a huge boost in that department as well. One other HUGE change is that each time the rear label door is opened, the tool will ask you what the current label width is, so you don’t start making labels and get an annoying message every time telling you it won’t fit the current tape size. Did we mention it resizes text automatically? That is an awesome feature that means most people are going to be able to pick up this tool and start making labels far faster with a very small learning curve. The Dymo Rhino 6000 label printer also comes stocked with more than 250 industry symbols and terms that may be incorporated into any of your labels with a minimum amount of hassle. If you are making lots of labels, or you have a “system”, the Rhino 6000 can save more than 1000 customized labels that you can recall later as needed.

The Dymo Rhino 6000 label printer meets all ANSI and TIA/EIA-606-A standards for labeling. It includes a single lithium-ion battery and a plug-in charger that connects directly to the Rhino label printer. The tool can also operate using 6 AA’s – perfect on locations you don’t have access to electricity. For pros thinking about making use of the 6000 for prolonged jobs, the lithium-ion battery is critical. The pack can be brought to full charge in just 30-45 minutes, potentially saving you hundreds of dollars per year in batteries. The Rhino 6000 has a handy 3-bar battery-life indicator located on the backlit LED screen and there is an auto-shutoff that guarantees you won’t go through batteries unnecessarily.

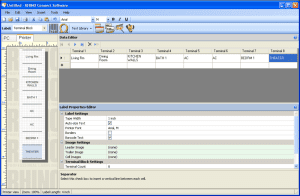

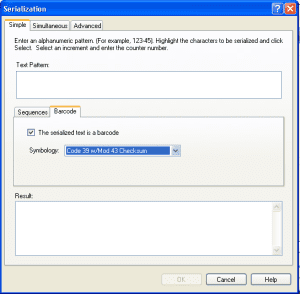

The Dymo Rhino 6000 label printer should receive an award for introducing professionals in the construction, electrical, and A/V installation industries to the notion of on-location label updating. Because the 6000 has 2-way communication with the PC-software, you can make all of your on-site labels back at the office. Got a problem or last-minute change? Not an issue, you can update and re-send the labels via email to the on-site operator which can reload and keep working. The Rhino 6000 is Dymo’s very first label printer to support this kind of feature. This is way cool – and since the communication goes both ways, any modifications made to labels on the jobsite can be used to keep the label database up-to-date back at the office.

Rhino Connect

Using the Rhino Label Makers

OK, so it does all this “stuff” – is it practical? Oh yeah. While the Rhino 600 isn’t the lightest label printer you can tote around, it makes up for it in features. If you want something a bit less to carry, you can opt for the Rhino 5200 kit. It doesn’t have automatic label cutting and the LCD screen is just a tiny bit smaller, but it’s a close second – and a bit more nimble to use. If you want to use Rhino Connect, however, the 6000 is your tool.

- FLEXIBLE NYLON – Perfect for curved or flat (but smooth) surfaces, these labels are available in white or yellow and serve well for wires, patch panels, boxes, bins, and more. They wrap easily around wire or cable. They aren’t for rough surface, however, and they are thinner than Vinyl.

- PERMANENT POLYESTER – For surfaces that may not be smooth or require a bit of extra grip, these labels have a shinier finish than Flexible nylon. They also give off a more finished look – perfect for name plates, patch panels, cabinets, shelves, bins, tools and any place you can’t afford the label to come loose.

- COLORED VINYL – This is the catch-all label for all general surfaces. You can use vinyl for outdoor and color-specific uses like warning messages, wires, patch panels, and more. The colors help improve visual recognition of labels and are still easy to apply and have great durability. The labels can also be used in direct sunlight and are ideal for outdoor surfaces.

- HEAT-SHRINK TUBING for wires and cabling – This are very specialized and unique labels that are essentially flattened heat shrink tubing that can take a label and work with the Rhino series of labelers. The high-quality polyolefin construction results in a 3:1 shrink ratio. Just add heat.

- NON-ADHESIVE labels are what you want for jobs like plastic covered patch panels, standard distribution blocks, and nameplates. If you need to print a label for a holder or sleeve you can do so quickly. Made of non-adhesive polypropylene, each label is strong and stiff.

Conclusion

Dymo has hit it out of the park with its Rhino line of labelers. If you print labels as part of your business, there really is no substitute. The label printer is as tough as the labels it creates and they’ve been doing it for over 3 decades. The new Rhino 6000 printer is sitting atop all other products on the market in our opinion. It’s a solid tool. You know, come to think of it, it’s the only label maker I really consider a “tool”. Dymo has thought through the needs of the contractor, electrician and journeyman with this product – and if you’re serious about your labels (and believe me, they reflect the quality of your work overall), you really need to give these a look and try them for yourself.