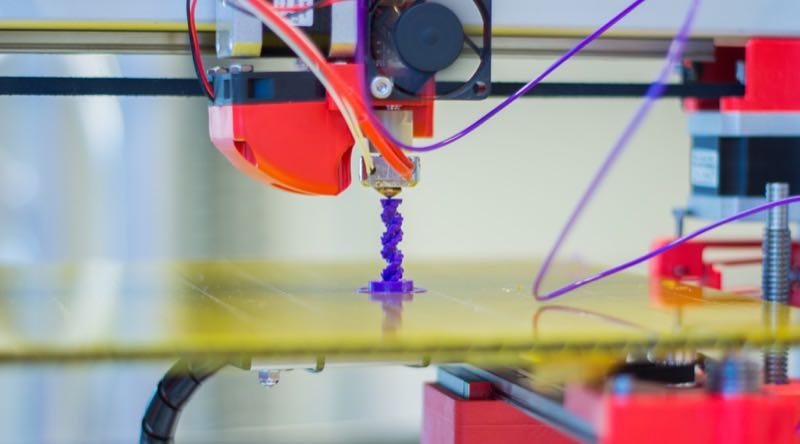

Whether you’ve been paying close attention or not, 3D printing technology has been steadily evolving since its inception in the 1980’s. More recently, however, 3D printing and additive manufacturing (or AM; the two terms are almost synonymous) have been developing by leaps and bounds. Basically, the process is simple: a 3D printer will use one of a variety of materials to build objects layer by layer. And the idea of 3D printing on the jobsite isn’t lost on us.

As the technology continues to improve and become more accurate, and as the cost of 3D printers and printer material has dropped, both companies and consumers are able to find new and innovative ways to utilize the technology. 3D printing has developed enough to be able to print objects in a variety of materials, from plastics and resins to concrete, metal, wood, and even bioengineered human skin and organs.

3D Printing In Government Agencies

For instance, NASA has been developing ways to use 3D printing in zero gravity. Medical supplies have already been 3D printed on the International Space Station, and NASA is looking into ways to develop the tech to replace complex rocket engine parts. NASA also plans to use 3D printing technology to create and build sustainable housing and habitats for deep space exploration.

Likewise, the US Military has developed ways to utilize the tech in deployment situations. Some soldiers in the US Marine Corps now have the capability to 3D print, from the field, tools to help in combat and reconnaissance missions quickly and at very little relative cost. Replacement parts that could take weeks to work through the supply chain to arrive can now be printed on site. The military has also found ways to use the technology in manufacturing lightweight and inexpensive drones, ammunition, and firearm accessories, among other things.

3D Printing On The Jobsite

How does this affect us on a more local and personal level? As 3D printing technology becomes a more financially and temporally viable alternative to traditional methods of production and manufacturing, the benefits will trickle down into our daily lives. 3D printing on the jobsite will become more commonplace as it becomes more cost-effective.

Take Contour Crafting Corporation, for instance. CC Corp, an early stage company, specializes in large-scale 3D printing and AM technology. Through the use of specially designed robotic and 3D printing systems, CC Corp intends to revolutionize home-building. They project that, eventually, their technology will enable the building of a house to take place in as little as a day. Additionally, building projects will take place at a much, much lower cost to the consumer. CC Corp also has its hands in infrastructure development, as well as a burgeoning plan for extraterrestrial structure development.

Final Thoughts

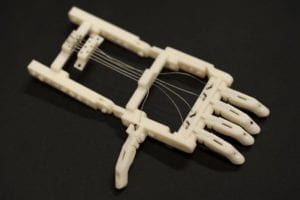

The benefits of being able to use 3D printing on the jobsite are obvious. Low-cost and extremely fast construction will help a lot of people, especially those consumers operating on a low-income budget. As the technology improves, people in remote areas will have access to medical supplies and prosthetics which, prior to this technological development, were either too expensive or too inaccessible to take advantage of. Things that might have taken weeks to arrive can now be printed out on site. In a lot of cases, the process is not much more complex than downloading a file and pressing “print”. Also, because the printing process only involves the material needed to complete the object, you see a reduction in material waste.

But, all of this will have implications for businesses, especially in the construction industry. And, it does bring up a lot of questions. How durable and safe will these structures be? How efficiently can this technology operate in the context of foundation, framework, plumbing, and HVAC applications (to name a few)? Maybe most importantly, how will these advances affect the labor force?

Of course, this sort of development might still be a long way off. Though progress seems steady, challenges surrounding logistics, functionality, and implementation still abound. Even so, keeping an eye on continuing developments might be a good idea. In the meantime, having the ability to create custom niche tools and parts on the fly is pretty neat.