It’s been said that you can’t have too many clamps and I’ve become a believer. From glue-ups to hold-downs, unless you can abut workpieces for screwin’ and gluin’ with some sort of superhuman strength for hours on end, you just won’t achieve good results. There are many types of clamps for as many purposes, but what if at least some of the F-clamps, clamps modified for bench dog holes, and holdfasts could be consolidated into one system with the added bonus of automatic adjustment to material thickness? Well that’s the promise of the Kreg Bench Clamp System.

Kreg is famous for its ingenious layout, joining, clamping, routing, and hardware installation solutions – including one of my favorite tools, the Kreg K4 pocket hole jig – so I expected good things from the Kreg bench clamp system.

First Impressions

The bench clamp has an unusual appearance because it appears to have no opposing side to match the force of the single jaw. It’s the woodworking equivalent of the question, “What’s the sound of one hand clapping?” Well, what’s the usefulness of one clamp’s jaw holding?

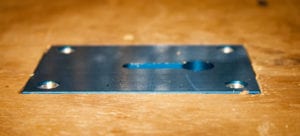

A lot, as it turns out. The clamp uses a keyhole plate recessed into the workbench and an anchor screw to make the workbench the opposing side of the jaw.

What’s more – not only can the clamp swivel 360-degrees but the clamp’s anchor screw slides out of the keyhole so the clamp can be moved out of the way when it’s not needed. This leaves a flat work surface intact but the option to have a versatile clamping station in a matter of seconds. However, if you’re unwilling to recess a hole for the clamp plate into your workbench, Kreg offers self-adhering rubber bumpers – spacers really – that lift the plate off of the workbench surface and give clearance for the anchor screw.

If the Automaxx works as advertised, it will be a big advantage. Automaxx is Kreg’s clamp technology that obviates tension and capacity knobs and screws found on most clamps. It automatically adjusts to material thickness with no user input. There is a tension adjust screw, but once it’s set, the Automaxx is designed to hold materials tightly no matter the size.

We Are The Clampions

The Kreg bench clamp system requires some setup for the clamp plate. Kreg’s instructions are clear and concise but you will need some tools to get the job done – namely a plunge router and a Kreg pocket hole jig. You could get around using the jig (what fun would that be?) but you’ll almost certainly want the router with top bearing pattern bit unless you want to score the workbench, pare back to the shoulders, and chisel away which, of course, is fun too. For this part of the project, I used the Triton TRA001.

Using four pieces of 3/4-inch stock, the routing template is made in a pinwheel fashion to ensure the router base is supported and stable throughout the entire cut. You’ll need a full-sized router, too – the template isn’t big but it’s too big for the small base of a trim router. The pieces are joined with pocket hole screws which means you need to be sure that the template stock you’re using is all of the exact same thickness.

If you’ve got some dimensional lumber, I’d suggest using that. Set the router’s depth stop to the template plus the clamp plate thickness, plunge and rout away. Of course, before starting, be sure the bit and router are in working order. If you feel the router pulling your hands or jerking, then the router isn’t powerful enough for the depth, the bit is too dull, or some combination of the two. Reset the depth stop to a shallower depth and progressively get deeper in two or more passes.

The rotary action of the bit creates rounded corners, so you’ll need to chop out the waste and square of the corners of the clamp plate’s recess.

Fit the clamp plate in the recess and mark out the keyhole. Remove the plate, drill two holes at each end of the keyhole channel, and use a chisel to remove the waste in between the two holes. Fit the plate back in the hole and slide the clamp with the anchor screw into the keyhole to verify it’s deep enough to accommodate the screw. If so, fasten the clamp plate to the workbench.

Jed Clampett

Once the setup is complete, the Kreg Bench Clamp System is quite easy to work with. Slide the anchor screw into the key hole and pull the clamp’s handle to clamp nearly anything to the workbench. Whatever you clamp is held very firmly. The strong jaw, clamp plate, and workbench combine for an iron grip.

The 3-inch jaw becomes the radius of a 360-degree clamping station. The Kreg Bench Clamp System also offers a 6-inch clamp, which will certainly meet about every benchtop clamping need there is.

At the risk of overstating the case, the Automaxx feature is brilliant. No longer do you have to fiddle with clamp tension or capacity adjustments – the clamp does it for you and holds materials of any thickness. I caught myself reaching for the clamp’s adjustment a few times until I finally remembered that whatever woodworking clamp magic Kreg has done to these clamps works extremely well – it’s just cool and convenient. I used the Kreg clamps to hold other templates, hold stock for cutting, and to hold pieces together for pocket hole fasteners.

The only complaint I have is a small one – I found the the rubber foot around the end of the clamp’s jaw tried to work its way off the clamp as the pressure was engaged, released, and engaged again. It’s not a big deal to push it back on, but it’s a small improvement that could help a lot.

In addition to the Kreg bench clamp system I tested, Kreg offers the heavy-duty bench clamp system that features a much larger clamp plate. The beauty of this system is in its portability – the large clamp plate takes the place of the workbench/clamp plate combo and immediately you can clamp just about anything anywhere. This is really pretty slick. Finally, Kreg also offers a clamp vice using the same system.

The Bottom Line

It takes a little setup but it’s really quite simple to get clamping with the Kreg Bench Clamp System. The clamp holds with an iron grip, creates a 360-degree clamping station, auto-adjusts to material thickness with Automaxx, and stows away easily when not in use. For $49.99, you’ll probably want more than one!

Kreg Bench Clamp System Features

- Includes 3″ (76mm) Bench Clamp, Clamp Plate, and mounting hardware

- Anodized-aluminum plate mounts flush with work surface

- Clamp automatically adjusts to match material thickness

- 3″ reach (76mm); clamps materials up to 33/4″ thick (95mm)

- Clamp features an adjustment knob for built-in pressure control

- Extra-large padded clamp spreads clamping pressure evenly

- Ergonomic padded grips prevent hand fatigue

- Compatible with Kreg Clamp Trak and Clamp Vise

Kreg Bench Clamp System Specifications

- Clamping Setup: 360-degree with auto-adjust

- Clamping Capacity: 3-3/4″

- Reach: 3″

- Included: Bench Clamp, aluminum Clamp Plate, mounting hardware

- Price: $49.99

Shop all Kreg products at Acme Tools!