US Saws Dust Buggy Mark III Makes Concrete Joint Cutting and Cleaning Easier Than Ever

When it comes time to restore concrete joints, it can be a daunting task. Scraping out the old material is one of the most time-consuming pieces of the puzzle. With the US Saws Dust Buggy Mark III, the job just got a whole lot easier – up to 10,000 linear feet per day easier.

We had some joint restoration to do at a local church, so we brought along the Mark III Dust Buggy to see how well it works.

10-Second Summary

- Single-piece cast aluminum base nails 4/1000″ precision

- OSHA-compliant via Objective Data without water

- Uses an 8″ blade to cut up to 2″ deep

- Capable of 10,000 linear feet of joint cleaning on an 8-hour shift

- $1650

US Saws Dust Buggy Mark III

Design

The US Saws Dust Buggy Mark III starts with a single piece of cast aluminum for its base and shroud. It’s an incredibly rigid design that’s able to maintain 4/1000″ accuracy as you track your joints. If you’re cutting joints rather than cleaning them, it’s easily able to track down a chalk line.

Moving up from the base, a square tube houses a telescoping handle. The design lets you adjust to infinite heights that is more than enough to cover the tallest users. The handle can come completely out and lets you reinsert it at 90°. It puts the rat tail grinder handle in its natural position and lets you work on joints parallel to the wall as close as 4″.

Cutting

For power, US Saws separates a 4.5 HP Metabo W24-230 MVT 9″ rat tail angle grinder so the motor powers the blade and the grinder’s handle makes up part of the chassis handle. It’s a 15-amp grinder and you need to plug into a 20-amp breaker to deal with the startup surge. Even on 20A outlets, we popped our breaker several times.

Just below the handle, there’s a serrated tooth-style blade height adjustment. The handle and trigger design make it easy to grip and adjust the to height you want without having to bend all the way down.

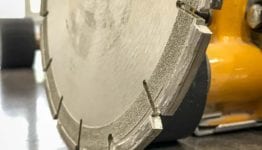

The saw takes up to an 8″ blade and cuts up to 2″ deep with an up cutting rotation. For our project, we only needed to cut 1″ deep and the 1/4″ thick diamond blade took care of the job in one pass.

Normally you need water to keep silica dust under control with a blade this size. However, US Saws did the testing and has a white paper for you based on their Objective Data to clear the saw for use with a vacuum. It falls under the grinder regulation, so you need 25 CFM for every 1″ of blade diameter – 200 CFM in this case. Most portable dust extractors don’t reach that level, Bosch and Hilti both have 300 CFM vacs. You can also look to US Saws for their industrial-level vacs and work with them to build the best start-to-finish system.

While there is a guide wheel on the front, there’s also an open window on the right side of the shroud that lets you see where the blade is at any time.

Price

You’re looking at $1650 for the US Saws Dust Buggy Mark III. It’s a Made in the USA tool that comes with a 25-year warranty on the chassis. If you happen to be attending World of Concrete in Las Vegas, be sure to stop by their booth so you can see it for yourself.

The Bottom Line

For our joint restoration project, the US Saws Dust Buggy Mark III made the job much easier and faster. Combined with their One Man Polymer Pump, we saved a couple of days worth of work thanks to a system that’s well-designed for the job.

With a long-term outlook on facilities management, the cost of getting set up with this system is much less than the increased cost of equipment maintenance on bad joints or a complete joint rebuild.