Dimide 1/4 Series Clamp Delivers Powerful Holding With the Power of Your Impact Driver

We use a ton of different clamps for the various projects we have going on around our shop. None look or operate quite like Dimide 1/4 Series Clamps, though.

Pros

- 1700 pounds of clamping force with a standard 18V/20V Max impact driver (designed to handle up to 2500 pounds)

- Modular design lets you swap jaw inserts, add a welding ground, or even custom build your own accessories

- Super-fast opening and closing

- Removeable T-handle when you need more control

Cons

- Even feathering the trigger, the clamp is sometimes too fast when you’re trying to keep everything aligned and use an impact driver

Recommendation

Just about any Pro or DIYer can take advantage of these clamps, but it’s with custom fabrication and production level work that we see the greatest benefits.Dimide 1/4 Series Clamp

The Project: Armored Safe Room Renovation

A client called me up and asked if we could renovate the master suite closet by adding steel reinforcement to create an armored safe room. The final product still needed to look like an unassuming closet. To make that work, we needed to fabricate steel plating all around the room.

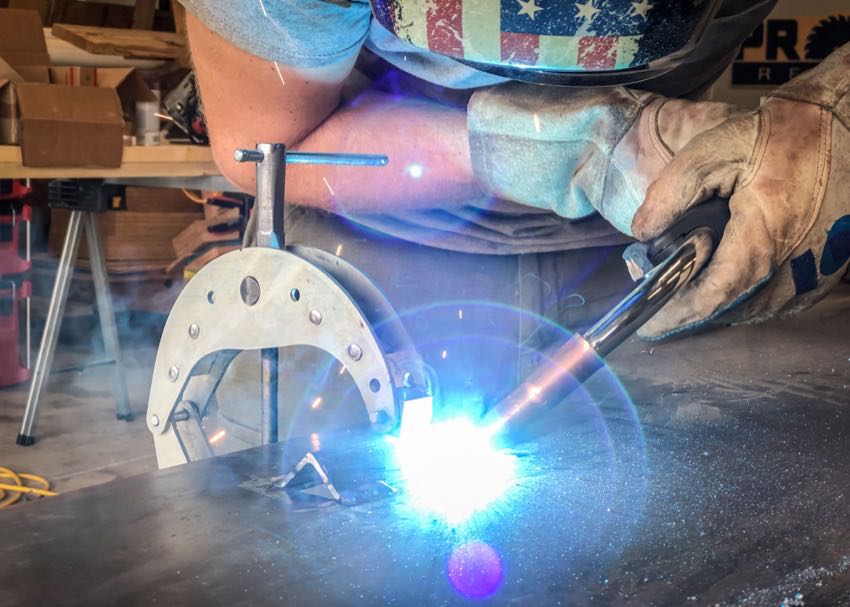

That was no problem, but building the door was where we had a lot of custom work. It needed to slide on tracks yet magnetically lock. We used our Dimide 1/4 Series Clamps to hold the various components in place while we welded them.

Impactful Design

One of the biggest problems we face with clamps is that our hands simply aren’t strong enough to take full advantage of the clamp’s physical design ability. The Dimide 1/4 Series Clamp swings thing in your favor with a 1/4-hex shaft you connect your impact driver on.

Just connect your impact driver (one-hand insertion collets are great for this!) and pull the trigger on your impact driver to clamp or release. The stronger the impact driver, the stronger the hold.

It’s a fast process, too. Fully opening or closing to its 6-inch capacity can take less than two seconds with some impact drivers. The shaft has threads on both sides, so both jaws are moving as it turns instead of just one.

The one thing you need to get used to is that reverse closes the clamp. My muscle memory is so ingrained to tighten in forward and loosen in reverse that I really had to think about what I was doing.

What If You Don’t Want to Use an Impact Driver?

Opposite the hex shank, there’s a T-handle with a detent that allows you to remove it if it’s in the way or you just don’t want it there. We found it very helpful when we were welding components for the magnetic lock plate and track slide hardware to the steel sheets of our armored safe room project.

While the impact driver is helpful and powerful, sometimes it’s too fast. Using the T-handle gave us more control to set the pieces exactly where we needed them for each weld.

Clamping Force

If you take a look at Dimide’s website, you’ll see they mention two numbers for clamping force: 1700 pounds and 2500 pounds. The clamp materials and design are rated for 2500 pounds. 1700 pounds is the amount of actual force they get from a DeWalt 20V Max impact driver.

The additional design rating leaves room for more powerful impact drivers that might show up in the future.

We wouldn’t turn to an impact wrench with a 1/4-inch adapter, though. If you want to go that route, the original Dimide clamp is designed to work with a 1/2-inch impact wrench.

A Customizable Clamp

Each Dimide 1/4 Series Clamp has a modular design. You can swap out jaw inserts, connect clamps, add a welding ground, and more. Because the design doesn’t have proprietary connections, you can even fabricate your own accessories for the type of work you do.

Each one of the mounting holes around the clamp offer a different connection point, limiting it only by your imagination. Those holes are also great for hanging the clamps when you’re done for the day.

Weight For It…

Despite the beefy, strong look of the Dimide 1/4 Series Clamp, it’s not super-heavy. Each one weighs 2.9 pounds in its stock configuration, though attachments will bring that up some.

Pricing

These 6-inch clamps run $39 when you order directly from Dimide. Considering what you get for the price, we don’t have a problem paying it.

If you’re interested in 1/2-inch impact wrench compatibility (and even stronger clamping), there are 5, 8, and 12-inch models that run $69, $99, and $239.

The Bottom Line

We love using our Dimide 1/4 Series Clamps anytime we’re doing metal fabrication. You have to be a little more careful when you’re clamping wood since even 12V impact drivers can produce a lot of clamping force on it. The beauty of its modular design is part of what helps you deal with the exact scenarios you most frequently come across.

Just about any Pro or DIYer can take advantage of these clamps, but it’s with custom fabrication and production level work that we see the greatest benefits.

Dimide 1/4 Series Clamp Specs

- Max clamping force: 2,500 pounds

- Impact wrench torque rating: 1/4″ Battery Powered Impact Driver

- Weight: 2.9 lbs

- Open Throat Depth (max): 4 Inches

- Closed Throat Depth (min): 3 Inches

- Clamp Opening Capacity: 6 Inches