Whether you’re in a dedicated fabrication shop or a project-based garage like ours, having a versatile welder on hand can save time, money, and trips to the metal shop. We partnered with Lincoln Electric to test out the WELD PAK 180i MP DV (K5257-1) — a compact, dual-voltage, multi-process welder that aims to handle MIG, TIG, Stick, and Flux-Core jobs in a single, easy-to-use unit. The results? Surprisingly professional welds from a surprisingly compact package.

Lincoln Electric Weld Pak First Impressions

Right out of the box, the Lincoln WELD PAK 180i MP makes a solid impression. Weighing in at just 35 pounds, this welder is easy to move around thanks to its top-mounted handle. For small shops, DIYers, or mobile applications, that’s a major plus.

Despite its small size, the setup is intuitive. You get a weld mode pushbutton and two dials to control voltage/amperage and wire feed rate. Behind the simplicity is a smart internal system that auto-adjusts depending on the welding process you select. A Quick Start Guide and procedure chart inside the side panel further simplify the setup—helpful touches for those who don’t weld daily.

Included Accessories

Here’s what Lincoln Electric includes with the 180i MP DV:

- 10-foot Magnum 100L MIG Gun

- Three wire welding contact tips: .025″, .030″, .035″

- Gasless and gas MIG nozzles

- 8-inch diameter spool adapter

- Harris gas regulator with 52-inch hose

- 10-foot Work clamp

- 10-foot Stick electrode holder

- 230V to 120V adapter plug

Pro Tip: The TIG torch and foot pedal are sold separately but are highly recommended if TIG welding is on your to-do list.

Using The Lincoln Electric Weld Pak 180i MP

To put the Weld Pak 180i MP through its paces, I tackled a project on my older Porsche 911. Great car, but one downside: it’s a little too quiet. Rather than drop big money on a new exhaust system, I opted for the “Gundo Hack”—cutting and welding 2-inch 304L stainless bypass pipes into the mufflers for a deeper sound and, according to my “butt dyno,” maybe even some extra horsepower.

TIG Welding Setup

For this job, TIG welding was the method of choice. The 180i MP doesn’t come with the TIG torch or foot pedal, so I picked up the Lincoln K1782-16 TIG Torch and K4361-1 foot pedal separately.

The setup process was smooth:

- Select TIG mode on the front panel.

- Plug in your accessories using the diagram and chart inside the cover.

- TIG runs electrode negative, so proper terminal connection was key.

- I used 1/16” ER308L stainless filler rod, 2% thoriated tungsten, and a 60-lb argon tank.

Before working on the Porsche exhaust, I practiced on flat stainless stock to dial in my amperage and gas flow. Preparation is key—close-fit joints, clean metal, and acetone wipes made all the difference in getting clean, strong welds.

TIG welding always has a learning curve—pedal modulation, filler rod feeding, and maintaining torch angle all require finesse. But even though I don’t TIG every day, I was able to lay down some decent beads. The WELD PAK 180i MP made dialing things in quick and predictable.

MIG and Stick Welding

Next, I set the machine up for stick welding to fabricate a steel bracket for one of our test rigs. Stick is the simplest setup: select the mode, plug your leads into the right terminals (negative for clamp, positive for electrode), and reference the included chart for amperage. The 180i MP handles up to 3/16-inch material and 160 amps, and after a minor amperage bump, I got smooth, consistent results.

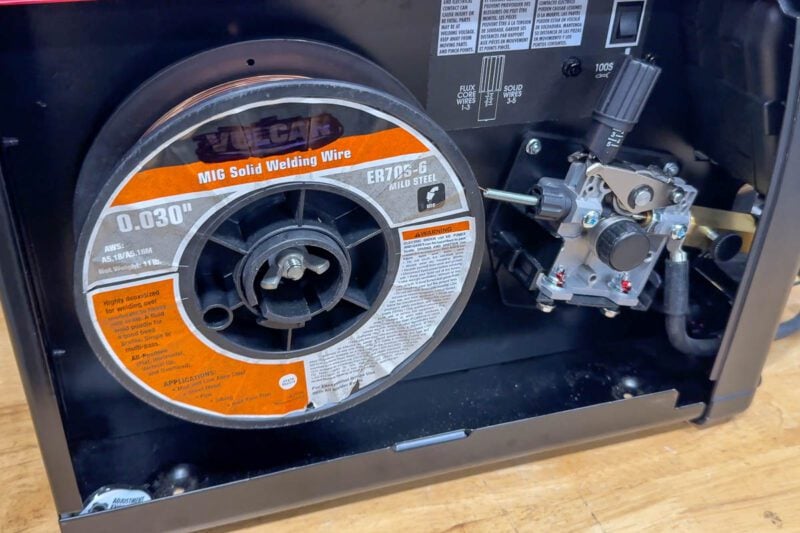

While I didn’t have flux-core wire on hand, I did test out MIG welding. Setup mirrored the other modes:

- Load your wire spool and install the MIG gun.

- Use the quick reference chart to dial in volts and wire feed speed.

- Connect your shielding gas.

In MIG mode, the welder reaches up to 165 amps at 22V with a 30% duty cycle, capable of welding up to 5/16” thick material. I used it to replace a steel base on one of our test setups, getting clean, consistent welds every time.

Final Thoughts and Pricing

The beauty of the Weld PAK 180i MP is how well it adapts to a wide range of light fabrication needs. Whether you’re building shelving, repairing a trailer, or modifying a car exhaust, this machine punches well above its weight.

After wrapping the Porsche project, I reinstalled the mufflers and fired it up. The sound? Just what I was hoping for—deeper and a little more aggressive, but not obnoxious. Whether or not the Gundo Hack added real horsepower is up for debate, but the satisfaction of doing the job myself was worth it.

For around $1100, the Lincoln Electric Weld PAK 180i MP DV delivers serious multi-process capabilities in a lightweight, user-friendly package. Add the TIG accessories, and you’re still well under what you’d spend on separate welders for each process. A 3-year warranty adds peace of mind.

If you’re a DIY welder, a mobile fabricator, or someone who needs flexibility without the clutter of multiple machines, the Weld PAK 180i MP should be on your shortlist.

Key Specifications

- Input Voltage: 120V / 230V Dual Voltage

- Weld Processes: MIG, Flux-Core, TIG, Stick

- Amperage Range: 25 – 180 Amps

- Duty Cycle (MIG): 30% @ 130A (120V) / 30% @ 165A (230V)

- Max Material Thickness: Up to 5/16” (MIG), 3/16” (Stick)