Anytime I see a new Milwaukee accessory with Nitrus Carbide in the name, it gets my attention. So, it was no surprise that I was genuinely curious when Milwaukee announced its new Nitrus Carbide Framing and Demolition Circular Saw Blade.

There are some bold claims surrounding this blade, and I’ve seen some impressive demos. I wanted to cut through the hype and better understand what makes this blade tick, so I jumped on a call with Project Manager Ryan Chaffee to learn more and help you understand its primary applications.

Modern Saws, Modern Challenges

Standard thin kerf blades have been great for cordless circular saws, but as the saws have grown more powerful, several issues have popped up. Especially on long rip cuts, blade wobble or warping can cause you to drift off your cut line. If you drift too far, you have to throw away the material and start over. With lumber prices being what they are, those costs add up quickly.

Then there are nails and screws. Whether it’s demolition, remodeling, or trimming excess material, hitting a fastener often damages blade teeth or rips them off completely. You can only deal with so much before you need to swap blades, adding time and expense to the job.

Enter the Milwaukee Nitrus Carbide Framing and Demolition Circular Saw Blade.

Milwaukee Nitrus Carbide Circular Saw Blades Can Handle the Heat

When blade wobble or warping is a concern, one of the easiest ways to deal with it is by making the blade thicker. In fact, Milwaukee’s Thick Kerf circular saw blades are highly effective for ripping clean wood and drifting is a real risk. The thicker material is more stable and resists drifting better.

The other way to deal with it is through better heat management. Since the Nitrus Carbide circular saw blade is a thin kerf design, keeping the blade cooler is key.

Cooling is important because as metal heats up, it becomes more malleable, which is why some blades are more prone to wobble and warp than others. The cooler you can keep the blade, the more stable it is, and the straighter your cuts are.

One of the blade’s most obvious physical characteristics is the ring of diamond cutouts surrounding the outside edge. As Milwaukee’s product team developed its latest generation of blade technology, it found this pattern was more effective at reducing heat buildup during long rip cuts.

Blade surface temperatures can reach 160° F or more, and Milwaukee’s diamond cutouts keep the blade several degrees cooler compared to other designs, helping you keep your cuts straighter.

A Strong Case for Milwaukee Nitrus Carbide Circular Saw Blades

Exactly zero people will be shocked to learn that if the teeth don’t stay on your blade, it’s going to have a hard time making cuts. That’s why Milwaukee welds the teeth to the backer instead of brazing them on.

Milwaukee isn’t the first to use welds to strengthen the bond. Irwin’s Weldtec blades did, and DeWalt’s Elite blades followed suit. However, Milwaukee uses a stronger weld that’s even more resistant to losing teeth. Compared to the brazing connection most blades use, Milwaukee’s weld creates a joint up to five times stronger.

It’s not just the weld that’s better—the teeth have an advantage as well. It starts with a premium tungsten carbide blend with a hardness dialed in to deal with nail and screw strikes. Each tooth uses more of this material, so if it loses some carbide, there’s plenty more to keep the blade working at a high level.

From there, each tooth gets a coating that helps resist damage when it hits a nail or screw, or when you’re cutting through abrasive material like shingles.

All of this comes together in a way that helps the teeth maintain their cutting edges longer than competing blades on the market. Between that and the welds keeping teeth in place better, Milwaukee Nitrus Carbide circular saw blades have a much longer usable life than others.

Backing it Up

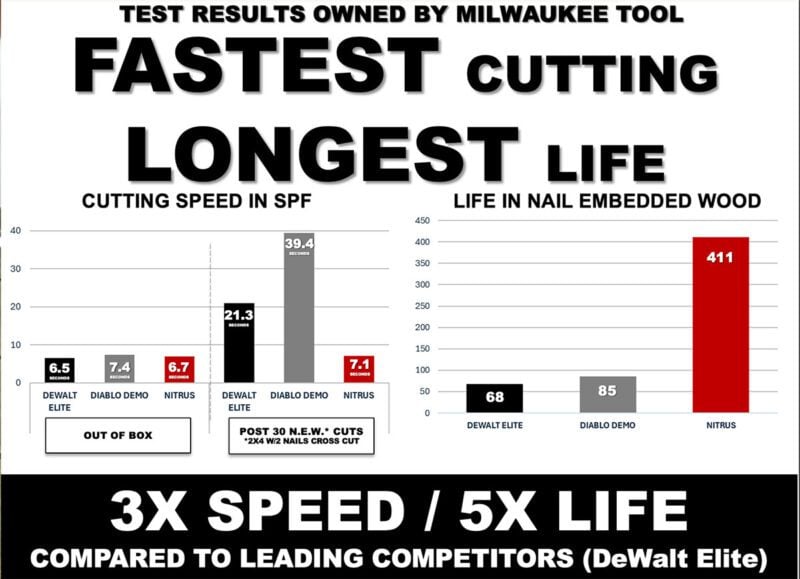

Here’s a look at how DeWalt Elite Series and Diablo Demo Demon blades compare to Milwaukee in a couple of test scenarios. These results are based on Milwaukee’s internal testing of brand-new blades making cross cuts in 2×4 lumber with two nails embedded in it.

| DeWalt Elite Series | Diablo Demo Demon | Milwaukee Nitrus Carbide | |

|---|---|---|---|

| New Blade | 6.5 seconds | 7.4 seconds | 6.7 seconds |

| After 30 Cuts | 21.3 seconds | 39.4 seconds | 7.1 seconds |

| Usable Life | 68 cuts | 85 cuts | 411 cuts |

You can see DeWalt’s blade was actually a little faster out of the box. However, the cutting time increased significantly for both DeWalt and Diablo once their teeth had some nail strikes under their belts, and their usable life was far shorter than Milwaukee’s.

Let’s give credit where credit is due, though. Getting dozens of cuts in a nail strike scenario is a testament to how far blade technology has come. However, Milwaukee’s ability to get hundreds of cuts in nail-embedded wood while maintaining high cutting speed shows just how next-level the Nitrus Carbide circular saw blade really is.

Milwaukee’s ability to get hundreds of cuts in nail-embedded wood while maintaining high cutting speed shows just how next-level the Nitrus Carbide circular saw blade really is.

Kenny Koehler, Editor-in-Chief

Milwaukee Nitrus Carbide Circular Saw Blades Price and Value

Milwaukee’s Nitrus Carbide circular saw blades are $25 each and a little less per blade if you buy multi-packs. That’s quite a bit more than the $10 framing blades or $15 – $20 demo blades you might be used to.

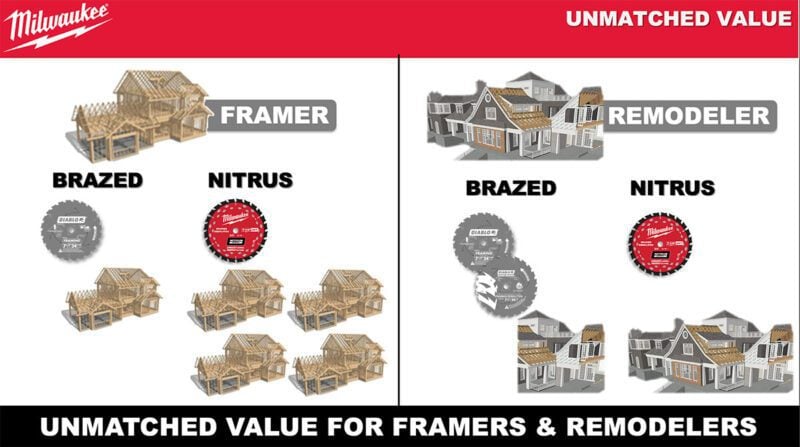

Consider the whole package, though. For starters, you don’t need separate blades for framing and demo—one Nitrus Carbide blade handles both. Plus, you don’t need the expense of having a saw for each blade type or spend the time switching blades if you’re only using one.

Then there’s the longevity. One Nitrus Carbide blade has enough life to frame out four full houses or remodel an entire house. That’s roughly four times more than competing blades. So, when you look at the amount of work you accomplish per blade, you actually come out way ahead with Milwaukee.

Framing Four Houses

- Milwaukee Nitrus Carbide: 1 blade, $25

- Competing Brands: 4 framing blades, $40 – $50

Remodeling a House

- Milwaukee Nitrus Carbide: 1 blade, $25

- Competing Brands: 2 framing, 2 demo blades, $50 – $65

Should You Buy Milwaukee Nitrus Carbide Circular Saw Blades?

For most people, the Nitrus Carbide circular saw blade is the all-purpose blade you need for nearly all framing and demolition applications. Its fast cutting speed and long life help you from both a productivity and cost standpoint.

The exception is those of you who make a lot of rip cuts. While the Nitrus Carbide blade can handle them, you’ll be better off with Milwaukee’s Thick Kerf blade for those consistent, high-volume rip cutting days.