In-Development Drones Could Save You Time, Money, and Labor

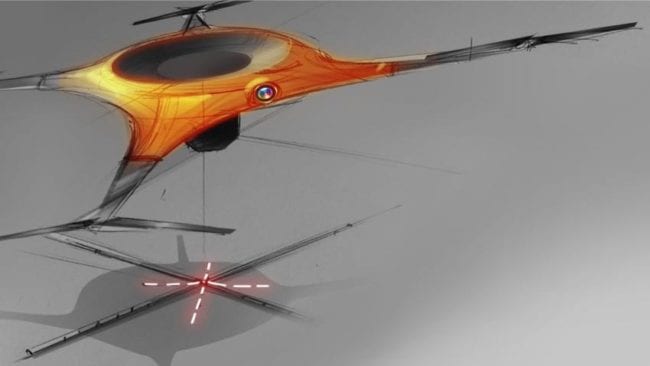

SkyMul, a company headquartered out of Atlanta, has a product in development for automating the rebar tying process for commercial construction. The SkyTy system uses drones to locate rebar intersections and then tie them off.

Droning On About Rebar

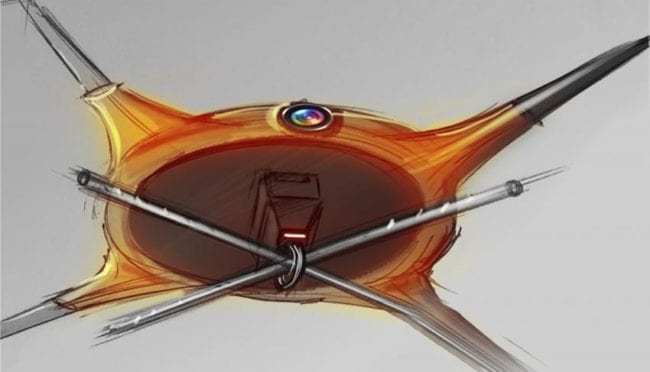

SkyTy drones use machine learning and computer vision to map out the work area and locate where the rebar intersects. Each drone can land, tie, and take off again to repeat the process.

Able to be set up in minutes, the SkyTy drones are fast to deploy. They operate autonomously to find the rebar intersections without the use of CAD files, site plans, or manual programming. Plus, the SkyTy drones are scalable, meaning that you can add them to a swarm. This means you can use them in parallel, increasing your throughput.

Each drone can operate independently of any other drone in the fleet. If a drone or its tie tool fails or breaks, you can swap it out seamlessly. Jobs can have varying conditions, like work area and schedule changes, but the SkyTy system can easily be scaled up or down to manage speed and productivity. SkyMul’s vision for the SkyTy drones is to combine the tenets of flexible automation and smart tools to form a modular, flexible, and robust system.

Technicians prep the drones with tie materials and fresh batteries, configure the swarm depending on the particulars of the job, and manage the operation. This lets you put your labor force on more challenging tasks.

The benefits of the SkyTy drones, as SkyMul calculates, are 84% less labor than hand-tying your rebar. Employing SkyTy promises to complete the work 1.9x faster than using your labor force physically do the work, and result in savings of around 13%.

Jobsite Automation Will Continue to Grow

Nearly every news report we see and interview we conduct with construction managers includes discussion about the skilled labor shortage. As long as the demand for construction remains high and the shortage continues, businesses will seek to find automation solutions to keep their projects (and profits) rolling forward instead of waiting.

SkyTy drones are a particularly interesting solution. We’ve seen drywall hanging robots and a lot of our thinking involves heavier labor-intensive tasks like that. But a lot of jobs don’t require a lot of heavy lifting. Imagine your crew laying our rebar and having drones run through the tying process while your human assets move onto a different part of the project. We already have rebar tying tools, it’s just a matter of putting one on a drone.

amzn_assoc_placement = “adunit0”;

amzn_assoc_search_bar = “false”;

amzn_assoc_tracking_id = “protoorev-20”;

amzn_assoc_ad_mode = “manual”;

amzn_assoc_ad_type = “smart”;

amzn_assoc_marketplace = “amazon”;

amzn_assoc_region = “US”;

amzn_assoc_title = “”;

amzn_assoc_linkid = “39cf95b1588bc39aa99f7a64f5ee2d26”;

amzn_assoc_asins = “B07ZTNQ7DM,B00V0NRDT2,B07JFM854F,B0050JFXC6”;

If SkyMul manages to get the drones to reload and recharge on their own, it’s conceivable to let the automation do its part overnight.

Here’s what PTR Managing Editor, Kenny Koehler had to say:

“The question of whether automation will replace human labor is answered—it’s here and it’s going to continue to increase. What remains unclear is the full potential of jobsite automation and whether it can close the labor gap enough to ever actually take jobs away from humans that want them.

“For now, solutions like SkyTy are a huge help is improving the efficiency and even quality of some of the work. If it can help you meet your deadlines or take on additional work, you’re going to be more profitable and the initial cost may well be worth it.”

For more information about the SkyTy drones, check out SkyMul.com. To see the drones in action, click here.