What is PEX pipe? Before we answer that question, let’s look at history, lest we doom ourselves to repeating it. Take a look at the water lines in any older house. You’ll probably find one consistent material being used: brilliant, shiny copper. Sorry, did I say brilliant and shiny? Scratch that. Look for copper tubing with dull, bluish-green scabbing all over it.

Table of contents

Why PEX Tubing Sounds Appealing

Before talking about PEX, it’s helpful to go back and discuss the reasons leading to its creation. To us, that means talking about “the way it used to be”. And by that, we mean the popular solution historically available to most plumbers prior to 2009 or so.

For the longest time, plumbers and builders installed copper exclusively in both residential and commercial settings. These provided sufficient and efficient pathways for water distribution systems. To plumbers, this also required (and still requires) lots of torch time. The professional plumber had to solder each and every copper pipe connection in the building. If you missed a solder joint or had a bad joint, you wouldn’t find out until you pressurized the system.

If (and when) you encountered a leak, you’d have to drain the system (after many choice words not suitable for this article). Then you would re-sweat the problem connection apart, dry it, re-clean it, and then solder it since more. This all takes A LOT of time. Manufacturers went out in search of an easier and more cost-effective way to transport water throughout the building. And did I mention that copper is really expensive!?

PVC, while introduced earlier, really took off during the 1970s and beyond. PVC, however, required glued connections for every directional change and also has issues with becoming brittle over time. PVC remains a very popular choice, but PEX offers some unusually distinct advantages.

Why Use PEX Tubing in Plumbing

So why use PEX tubing or piping in plumbing installations over PVC or copper? First, this alternative to copper and PVC water lines offers rapid installation—often cutting times by half. And PEX has technically been around for some 50 years now, it’s gaining momentum in the residential plumbing sector.

In this pursuit, PEX tubing (also known as cross-linked polyethylene for the nerds in all of us) makes the running of water lines a heck of a lot easier and cheaper than copper. But to make life more interesting the developers came up with three different grades of PEX – PEX A, PEX B, and PEX C.

What is PEX Tubing or Pipe? Three Grades

The different ratings you see on PEX (A, B, and C) refer to the manufacturing process rather than thickness ratings. PEX-A uses a peroxide method, PEX-B gets silane, and PEX-C goes through an electronic irradiation process. But those processes result in different characteristics and each manufacturer has to choose what they’re going with.

PEX-A (Major Manufacturer: Uponor)

PEX-A offers the highest flexibility of all the PEX types available and offers the highest degree of cross-linking. Users can repair kinks in the tubing using a heat gun as well. PEX-A has no coil memory, which means that it won’t try to return to its original shape in the coil. One of the downsides to PEX-A revolves around price; PEX-A costs anywhere from 100%-160% more than PEX-B. It also bursts at lower pressures than PEX-B. This type tends to lack consistency in wall thickness, and because of the manufacturing process, PEX-A tends to display a higher rate of chemical leaching. This can cause concerns in plumbing applications.

PEX-B (Major Manufacturer: Viega)

PEX-B displays high resistance to chlorine and oxidation and offers the highest bursting pressure. Because of these qualities, PEX-B can last up to 40 years, making it a solid choice for plumbing applications. It costs less than PEX-A and PEX-C and has the lowest dimensional tolerances. However, it is more rigid than the other two PEX types, and it displays noticeable coil memory. It offers a lower cross-linking ratio than PEX-A. As opposed to being able to fire up the heat gun, repairs generally have to be made through splicing the piece and then coupling it back together.

What is PEX-C Tubing?

PEX-C is the newest of the PEX types and offers little to no coil memory. It is more pliable than PEX-B, and in terms of manufacturing processes, it is more environmentally friendly. However, PEX-C shows a tendency to develop cracks, kinks easily, and does not cross-link particularly easily. It has even suffered from involvement in a class-action lawsuit for its proneness toward early oxidation.

4 Methods to Install PEX Tubing or Pipes

SSC – Stainless Steel Clamp

The clamp-ring connection method involves sliding a ring over your PEX tubing, and then your tubing over a specialized fitting. The ring is then positioned over the middle of the fitting’s male end and tightened down with a stainless steel clamp ring crimping tool. Closely related to the clamp method is c=standard crimping.

Push-Fit

The push-fit method requires no tools but does require special couplers. The PEX is pushed into the specialized coupler, which contains a stainless steel barbed ring. The ring closes itself around the PEX tubing. This method is one of the easiest of the connection methods.

Expansion

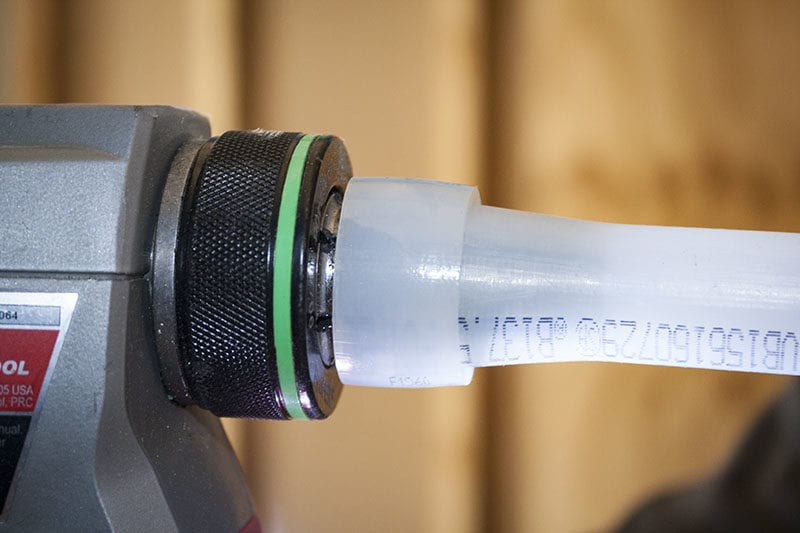

The expansion method uses a specialized tool like the Milwaukee M12 FUEL ProPEX Expander that expands the end of the PEX tubing so that it can fit over a brass fitting. A plastic sleeve slides over the connection point. After the PEX tubing shrinks back down to its original shape around the fitting, you’re done! The expansion method is quick and reliable. We also have a handy installation guide on how to install PEX tubing with expanders.

Compression

Compression fittings involve an insert that gets pressed into the end of the PEX tubing. A nut and a nylon sleeve slide over the end of the tube. The PEX then slides into the fitting, where the nut tightens down over the sleeve, sandwiching the PEX tubing between the fitting and the nylon sleeve.

Tools for Installing and Expanding PEX Tubing

A variety of tools let you easily install PEX tubing, however, we wanted to list some of the ones we’ve reviewed. If you want to get the real story on how they work and save you time, these reviews should give you everything you need: