When it comes to finding the best impact driver, is your top priority power? Speed? Size? Price? We’ve tested dozens of impact drivers over the years, and we have more choices than ever. In this guide, I’ll walk you through the ones that rose to the top in our testing. I’ll also share what we look for when we’re evaluating these tools to help you make a more informed decision.

Best Impact Driver Top Picks

- Best Overall: Milwaukee M18 Fuel 2953

↓ Jump to this Impact Driver - Best Compact: Metabo HPT 18V Triple Hammer WH18DCM

↓ Jump to this Impact Driver - Most Powerful: Flex 24V Quick Eject FX1371

↓ Jump to this Impact Driver - Best 12V: Milwaukee M12 Fuel 3453

↓ Jump to this Impact Driver - Best Quiet/Hydraulic: DeWalt 20V Max DCF870

- ↓ Jump to this Impact Driver

- Best for the Money: Skil PWRCore 20 ID6739B-10

↓ Jump to this Impact Driver

Jump to These Sections for More Information

- More Impact Driver We Recommend

- Best Impact Driver Bits

- How We Made Our Choices

- What to Look for When Buying an Impact Driver

- Why You Can Trust Pro Tool Reviews

Best Overall Cordless Impact Driver

Milwaukee M18 Fuel 2953

- Top Speed: 3900 RPM

- Max Torque: 2000 in-lbs

- Impact Rate: 4400 IPM

- Length: 4.5 in

- Weight: 2.2 lbs bare

- Price: $149 bare, $299 kit

- 2-Tool Combo Price: $399

Pros

- Compact, lightweight design

- Excellent performance

- 3 standard modes plus an assist mode

- Noticeably smooth trigger acceleration

- LED light ring

- 5-year warranty

Cons

- Expensive

If you’re looking for the best combination of performance, size, and weight, look no further than Milwaukee’s M18 Fuel impact driver in its fourth generation. Second only to Flex in our performance tests, it’s significantly smaller and lighter. Pros also can’t ignore that Milwaukee has one of the most extensive selections of tools that work on M18 batteries.

Milwaukee’s bumped up the speed on the latest model. It increases 300 RPM to drive at a maximum speed of 3900 RPM. That also comes with a slight increase in impact rate to 4400 IPM. Notably, Milwaukee made some adjustments to the trigger. It’s now capable of smoother acceleration to give you more control over your screw starts. I find that particularly helpful when starting self-tapping screws.

All of the improvements come with absolutely no change in weight. You can find a cheaper impact driver, but you won’t find a better tool for lightweight screwdriving performance.

Best Lightweight and Compact Cordless Impact Driver

Metabo HPT 18V WH18DCM

- Top Speed: 3700 RPM

- Max Torque: 1859 in-lbs

- Impact Rate: 4000 IPM

- Length: 4.5 in

- Weight: 2.0 lbs bare

- Price: $129 bare, $149 kit

- 2-Tool Combo Price: Not Available

Pros

- Lightweight and compact

- Fast driving speeds

- LED light ring

- Excellent value

- Lifetime warranty

Cons

- Not as powerful as some models

If you’re looking for the most compact impact driver, DeWalt’s DCF850 and Milwaukee’s M12 Subcompact 3450 are excellent options. However, you only need to gain about 1/2 an inch in length to get to some of the highest-performing model available, and that’s a trade-off worth making.

With models from Makita, Metabo HPT, and Milwaukee at 4.5 inches, you have several great options. Balancing solid performance with a lighter working weight, Metabo HPT’s 18V Triple Hammer is my recommendation as the best compact impact driver.

Metabo HPT raised eyebrows when it launched its innovative Triple Hammer impact driver design. It’s not a gimmick, either. With three hammers instead of the standard two, every rotation gets an extra strike, improving driving speeds across the board.

It’s now had time to prove itself in the field as a design that offers solid performance and the durability to thrive on professional jobsites. On top of that, the 18V model is lightweight and compact, making it a go-to choice that pairs well with a compact 2.0Ah battery. Plus, the newest version includes a specific mode for working with nuts and bolts.

But it’s the price that seals the deal. The bare tool is $129—a little lower than Milwaukee and DeWalt. The kit price with two 2.0 batteries and a charger is just $149, though. I don’t think you’ll find anywhere close to the performance and design Metabo HPT offers if you’re shopping in the same price range. Plus, this model has a lifetime warranty to go with it.

Most Powerful Cordless Impact Driver

Flex 24V Quick Eject FX1371A

- Top Speed: 4000 RPM

- Max Torque: 2500 in-lbs

- Impact Rate: 4450 IPM

- Length: 4.8 in

- Weight: 2.8 lbs bare

- Price: $159 bare, $179 – $279 kit

- 2-Tool Combo Price: $379

Pros

- The most powerful impact driver we’ve tested

- 3 standard modes plus assist modes

- Innovative Quick Eject bit feature

- Excellent value

- Lifetime warranty with registration

Cons

- Heavier than most impact drivers

Flex has held the best performance award since it first launched several years ago. In 2025, DeWalt became a serious challenger with its DCF860 high-torque model, but Flex still had the advantage in our head-to-head tests. That’s a real testament to just how far ahead of the competition Flex was (and is) with its first-generation impact driver.

Solid with a standard battery, it notches even higher performance with a Stacked Lithium battery. In our tests, it took first in nearly every test we ran, even against other brands with advanced batteries.

While it doesn’t feature one-hand bit insertion or active spring ejection, it does have a Quick Eject feature. You simply push the button just above the trigger to open the collet without having to take your hand off the handle. It’s a convenient way to switch bits quickly.

The trade-off is that this model is a bit larger and heavier than other top performers. However, it’s also priced a bit lower and offers a lifetime warranty when you register the tool.

Best 12V Cordless Impact Driver

Milwaukee M12 Fuel 3453

- Top Speed: 3600 RPM

- Max Torque: 1500 in-lbs

- Impact Rate: 4000 IPM

- Length: 5.0 in

- Weight: 2.0 lbs bare

- Price: $139 bare, $169 kit

- 2-Tool Combo Price: $229

Pros

- Outstanding performance in the 12V class

- 3 standard modes plus an assist mode

- One-hand bit insertion

- LED light ring

- 5-year warranty

Cons

- Lower performance than top 18V/20V Max models

Milwaukee’s third-generation M12 Fuel impact driver made significant improvements in performance and size, making it the best 12V impact driver for performance-driven people like us.

In performance, it drives more like a compact 18V/20V max impact driver than a 12V model. Yet its size and weight are undoubtedly compact.

Milwaukee’s design is solid, with a self-tapping screw mode to go on top of its three standard modes, one-hand bit insertion, and three-LED light ring surrounding the collet.

Even if this was a close race (and it’s not), Milwaukee’s deep, trade-focused M12 battery system sets the 3453 apart from other brands you might be considering. And if that’s not enough, keep in mind Milwaukee backs this model with a 5-year warranty.

Best Quiet/Hydraulic Impact Driver

DeWalt 20V Max DCF870

- Top Speed: 3000 RPM

- Max Torque: 500 in-lbs

- Impact Rate: 4200 IPM

- Length: 4.0 in

- Weight: 2.2 lbs bare

- Price: $219 bare, $319 kit

- 2-Tool Combo Price: Not available

Pros

- Much quieter than a standard impact driver

- Higher performance than other hydraulic competitors

- Compact

- Lightweight

- LED light controls with timer up to 20 min

Cons

- Lower performance than standard impact drivers

- Expensive

Milwaukee’s Surge hasn’t had much competition as the best quiet impact driver. DeWalt finally topped it with its DCF870 hydraulic impact driver.

In performance, DeWalt pushes the torque higher to 500 in-lbs and bumps the impact rate up to 4200 while matching the M18 Fuel’s 3000 RPM. While that’s not straight-up domination, it does raise the bar.

Where DeWalt seals the deal is with the design. Leaning on the concept of the super-compact DCF850, the head is just 4 inches long. That’s significantly more compact than any other quiet impact we’ve tested. Plus, it’s lighter than most of its competition as well.

The tradeoff is that you don’t get the kind of performance you do from standard impact drivers, but that’s the case no matter which quiet model you choose. The bigger consideration is that this is an expensive impact driver, coming in $50 more than the M18 Fuel as a bare tool.

Best Cordless Impact Driver for the Money

Skil PWRCore 20 ID6739B-10

- Top Speed: 3100 RPM

- Max Torque: 1800 in-lbs

- Impact Rate: 3950 IPM

- Length: 4.9 in

- Weight: 2.0 lbs bare

- Price: $69 bare, $100 kit

- 2-Tool Combo Price: $149

Pros

- 3 standard speeds plus control mode

- LED light halo

- One-hand bit insertion

- Excellent value

- 5-year warranty

Cons

- Lower driving speed than Pro models

Skil once again earns a value accolade as the best impact driver for the money. With 1800 in-lbs of torque, it hits as hard as many Pro models we’ve tested. It gives up a little performance in the speed department, though.

This is a well-built impact driver, and Skil has the confidence to back it with a 5-year warranty—much longer than most DIY brands. At the same time, this iteration is much more compact and lighter than previous models. Wrapping in one-hand bit insertion and an LED halo to light up your work area makes it convenient to use as well.

All this comes with a very approachable price tag. The bare tool is just $69, the kit is under $100, or you can get a combo that comes with a compact brushless drill for under $150. I haven’t seen anything else that combines the performance, size, features, and price as well as Skil has done with this model.

More Impact Drivers We Recommend

Bosch 18V GDR18V-1950

- Top Speed: 3400 RPM

- Max Torque: 1950 in-lbs

- Impact Rate: 4000 IPM

- Length: 4.5 in

- Weight: 3.0 lbs bare

- Price: $179 bare

- 2-Tool Combo Price: Not available

Pros

- Compact

- Three standard modes plus assist modes

- One-hand bit changes

- 5-year warranty

Cons

- No kit available

Bosch’s latest impact driver doesn’t set the world on fire with tons of bells and whistles, but there’s not much to complain about either. Torque has been noticeably behind its competition previously, but this model is much more in line with what we like to see.

It’s a compact design that maintains Bosch’s solid ergonomics. A couple of assist modes help you maintain better control while you’re fastening and one-hand bit changes make things a little more convenient.

The only slight twinge of disappointment I have is that there’s no hybrid drive model (yet). Bosch’s 2-in-1 square and 1/4-inch hex design is brilliant, and this impact driver has the power to be more effective as a compact impact wrench than previous versions.

DeWalt 20V Max High-Torque DCF860

- Top Speed: 3800 RPM

- Max Torque: 2500 in-lbs

- Impact Rate: 4500 IPM

- Length: 4.8 in

- Weight: 2.7 lbs bare

- Price: $219 bare, $319 kit

- 2-Tool Combo Price: Not available

Pros

- Excellent performance

- LED light ring

- LED work light mode

Cons

- Heavy

- Expensive

After setting a new standard for compact with its DCF850, DeWalt set its sights on improving performance. With the launch of the DCF860, DeWalt made massive gains in that department. Sporting significantly higher torque and speed, its by far the highest performing model in the line.

There’s a bit of a weight penalty that comes with it—unsurprising considering you need a larger motor and potentially beef up the hammer and anvil as well. It manages to remain reasonably compact, coming in under 5 inches.

There aren’t a ton of special features to talk about. Most of them are tied into the LED system. 9 LEDs create a ring around the collet. Most importantly, you have some control over how they react when you pull the trigger, including turning them off completely or running for 20 minutes as a work light.

Greenworks 24V IGS402

- Top Speed: 2600 RPM

- Max Torque: 1950 in-lbs

- Impact Rate: 3800 IPM

- Length: 5.0 in

- Weight: 2.0 lbs bare

- Price: $89.99 bare, $119.99 kit

- 2-Tool Combo Price: $149.99

Pros

- Affordable

- Lightweight

- Compact

- Solid power for the price

Cons

- Slower than competing models

- Single speed

Greenworks has a couple of excellent DIY-focused impact drivers, and my favorite between the two is the more compact IGS402. Sporting an impressive 1950 in-lbs of torque, it has the power to handle most of your fastening projects, though the speed is a little lower than competing models. The overall weight is low and the design is reasonably compact for this class.

The downside is that this is a single-speed model. However, the price is so affordable that its value overcomes that obstacle. If three speeds is a must for you, step up to Greenworks’ more powerful ISD401 model.

Makita 40V max XGT GDT01

- Top Speed: 3700 RPM

- Max Torque: 1950 in-lbs

- Impact Rate: 4400 IPM

- Length: 4.8 in

- Weight: 2.2 lbs bare

- Price: $224 bare, $449 kit

- 2-Tool Combo Price: $469

Pros

- Excellent performance

- 4 standard modes plus several assist modes

- Quick mode selection button below the collet

- Compact

Cons

- Expensive

Makita’s XGT impact driver starts with the foundation of its successful 18V LXT models and builds on it for the 40V max line. With 3700 RPM, 4400 IPM, and 1950 in-lbs of torque, it’s a little faster and a lot stronger. It showed in our tests that this GDT01 clearly has an advantage over Makita’s 18V models.

The higher-performing design doesn’t add much bulk, though. With its 2.5Ah battery, the GDT01 is less than 0.2 inches longer and just 0.3 pounds heavier. It’s also one of the most expensive impact drivers on the market.

One of the coolest features Makita includes is a button above the trigger that lets you cycle through the four standard modes. It’s not programmable like the XDT16 was, but super-helpful since you don’t have to look down from your work or take your hand off the tool to switch modes.

Makita fans may note that the GDT02 was released in 2023. However, the GDT01 is still the higher-performing model for the 40V line.

Milwaukee M18 Fuel Surge 2760

- Top Speed: 3000 RPM

- Max Torque: 450 in-lbs

- Impact Rate: 4000 IPM

- Length: 5.0 in

- Weight: 2.8 lbs bare

- Price: $169 bare, $329 kit

- 2-Tool Combo Price: $429

Pros

- Much quieter than a standard impact driver

- Excellent performance for the quiet class

- M12 Fuel version available with similar performance

- 5-year warranty

Cons

- Lower performance than standard impact drivers

- Heavy

It’s hard to believe Milwaukee’s M18 Fuel Surge has been out for more than five years. Perhaps more impressive is that it’s been the leader in the class all that time and was just recently eclipsed by DeWalt’s DCF870.

Sporting the profile of a standard impact driver, its quieter operation makes it a go-to for screwdriving jobs in occupied spaces or when you just don’t feel like dealing with the extra noise. While DeWalt does have the advantage in size and weight, its torque is only marginally higher, and the speed is the same, keeping Milwaukee’s performance near the top of the charts for this class.

If the M12 battery system is more your style, the M12 Fuel Surge has very similar performance in a smaller, lighter package.

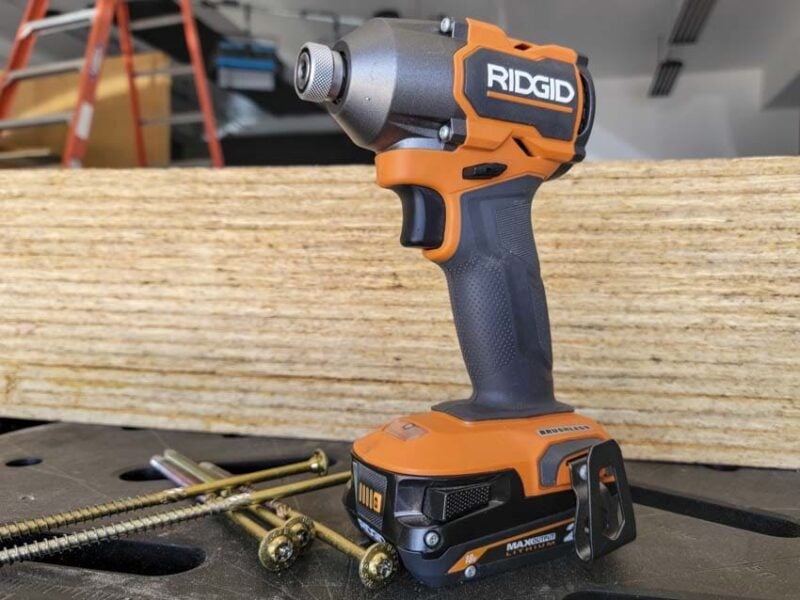

Ridgid 18V R862312

- Top Speed: 3400 RPM

- Max Torque: 2400 in-lbs

- Impact Rate: 4200 IPM

- Length: 5.1 in

- Weight: 2.3 lbs bare

- Price: $139 bare, $199 kit

- 2-Tool Combo Price: $349

Pros

- Excellent performance

- 3 standard modes plus an assist mode

- Excellent value

- Lifetime service agreement (registration required)

Cons

- A little larger and heavier than premium models

With the release of the R862312 impact driver, Ridgid made significant performance gains while making similarly drastic improvements to its size and weight compared to previous versions. This model’s torque is near the top of the charts and the speed is very much in the mix with premium brands.

This is a relatively straightforward model without a lot of bells and whistles (which many Ridgid fans appreciate), though it does have a self-tapping screw mode.

As we expect from Ridgid, the price is very reasonable, and the sub-$200 kit even includes an advanced Max Output battery rather than a standard pack. If you want the best value, grab the combo that includes the impact driver, Ridgid’s newest high-performance brushless hammer drill, and two Max Output EXP batteries packed in a hard case for $349.

Ryobi 18V One+ HP Brushless PBLID04

- Top Speed: 3400 RPM

- Max Torque: 2300 in-lbs

- Impact Rate: 4200 IPM

- Length: 5.2 in

- Weight: 2.5 lbs bare

- Price: $129 bare

- 2-Tool Combo Price: Not available

Pros

- Outstanding performance for the DIY class

- 3 standard modes plus an assist mode

Cons

- No kit option

- A little heavier than the previous model

With the launch of the second-generation HP Brushless impact driver, Ryobi’s continued increase in performance and reduction in size is challenging some Pro brands and daring other DIY competitors to raise their game.

While still a little larger and heavier than we expect from premium models, the performance level is solidly in the Pro class. Teasing value-minded Pros even more, there’s a self-tapping screw mode to go with its three standard driving modes.

At the outset, the PBLID04 is only being offered as a bare tool. I’d love to see a kit, or more importantly, a 2-tool combo that pairs it with the Gen-2 hammer drill and a couple of High Performance batteries.

Best Impact Driver Bit Set

Milwaukee Shockwave Impact-Rated Bits

Bits designed for use in impact drivers have to flex to absorb the torsion of the impacts, or they risk breaking, especially when fastening metal. Every manufacturer has a delicate dance to perform between bit hardness, flex, and the variety of materials people like us use them on.

We’ve had good success using Milwaukee’s Shockwave line of impact-rated bits. The range is impressively wide with standard driver bits, nut drivers, specialty bits, and even drill bits with a hex shank to fit in your impact driver. There are also plenty of combo kits to save you some money over buying bits in individual or smaller packs.

Check them out for yourself and see if they outperform the bits you normally use.

How We Made Our Choices

Best Impact Driver Overall

To earn the most coveted accolade as the best overall, an impact driver has to have an optimal balance of performance, features, size, and weight. Price is secondary.

Best Compact Impact Driver

In a compact impact driver, we’re looking for the best combination of access and performance. Weight and features are secondary and price is the lowest priority.

Most Powerful Impact Driver

Driving power is the only priority in this category, but putting a bigger torque number on the spec sheet isn’t enough—each model has to prove it in our tests.

Best 12V Impact Driver

Similar to the best overall, the 12V overall winner has to have an optimal balance of performance, features, size, and weight. Price is secondary.

Best Quiet/Hydraulic Impact Driver

To top the quiet impact driver charts, we’re looking for a hydraulic model with the best blend of performance, features, size, and weight. Price is a secondary consideration.

Best Impact Driver for the Money

To earn our top value pick, an impact driver has to balance performance, features, size, weight, and price. The depth of the battery system and warranty coverage are secondary considerations.

What to Look for When Buying an Impact Driver

Performance

Impact drivers benefit from higher speeds and greater torque than their drill counterparts. Their speed helps drive small fasteners more quickly while the power and impacts tighten or break loose fasteners better than drills.

However, it is possible to have too much power. When you’re installing self-tapping screws into metal, for example, the high torque of an impact driver can easily shear off screw heads or break bit tips. That’s why it’s best to have a model with multiple modes. Better yet, assist modes like a self-tapping screw mode can let you use the full speed and torque available while reducing the risk of damage.

Size and Weight

One of the reasons we love impact drivers is that they tend to be smaller and lighter than drill drivers. They can reach into tighter areas and are less fatiguing when you’re working overhead.

With today’s technology, having a model that’s less than 5 inches across the head and under 2.5 pounds as a bare tool is easily achievable—and almost a requirement for Pro-grade models.

Grip

While we don’t come across many tools that have a terrible grip, some are better than others. Slide packs are important because they give design teams more freedom in handle and grip design. Stick packs have to fit into the handle and tend to be thicker than slide pack designs.

However, even the ergonomic design of tools with stick packs is improving. The big thing is to pick up a few different brands in the store and see which handle is most comfortable for you. Even if the exact impact driver you want isn’t on display, most every brand uses the same handle shape and overmold across all their pistol grip tools.

Feature Set

Sales 101 will teach you that every feature must have a benefit. As you consider the feature set to help determine the best impact driver, look for features that have tangible benefits. Here’s a typical list of what we look for:

- Brushless Motor: Significantly improves performance, runtime, and service life.

- Standard Speed Modes: Ideally, you want at least three standard speed modes to manage light, medium, and heavy fastening jobs.

- Special/Assist Modes: Modes specifically designed to help reduce the risk of damage, loosing fasteners, or other benefits

- Smart Features: These can include inventory management, tracking, and even custom control settings.

- LED Lights: LED lights that surround the collet do a better job of eliminating shadows and some models even offer control settings for them.

- Bit Ejection: Having a spring-loaded bit ejection can make swapping bits easier.

- Bit Insertion: Some collets accept bits without having to pull up on the mechanism, making it a one-handed operation.

Price and Value

The value a tool offers will be different for everyone, depending on what features, performance, and price you prioritize the most. Regardless, it’s the sum of what you get compared to the price you pay that determines the value for you.

Why You Can Trust Pro Tool Reviews

Ever check out a “review” site and can’t tell if they actually test tools or if they just “recommend” the Amazon top sellers? That’s not us. We won’t recommend anything unless we’d use it ourselves, and we don’t care who the primary retailer is. It’s all about giving you a legitimate recommendation and our honest opinion of each product.

We’ve been in business since 2008, providing tool reviews and reporting on industry news in the construction, automotive, and lawn care industries. Our Pro reviewers work in the trades and have the skills and experience to know whether tools can perform well in the field.

Each year, we bring in and review more than 250 individual products. Our team will put our hands on hundreds of additional tools at media events and trade shows throughout the year. The end result is information you can trust because of the editorial, scientific, and real-world professional experience we collectively utilize every time we pick up and test a tool.