Tungsten carbide is all over the power tool industry. Often shortened to just carbide, there are actually more blends than just with tungsten. Quite often, we get asked the question: “What is tungsten carbide?” To give you the best possible answer, we interview manufacturers. We wanted to dig a little deeper into this material to see how it makes accessories more effective.

Table of contents

What is the Tungsten Carbide Material?

The general term “carbide” simply means it’s a compound using carbon and a less electronegative element. Tungsten carbide contains equal parts carbon and tungsten and starts life as a powder.

The powder goes through a sintering process for use in many different products, including accessories like drill bits and saw blade teeth.

It’s a robust compound that can survive tough applications like drilling through aggregate. That toughness is why I chose it for my wedding band instead of gold since I work with power tools every day.

Most accessories aren’t pure carbide. On circular saw and reciprocating saw blades, it’s just the individual teeth. On most drill bits, it’s just the cutting edges. The rest of the accessory is usually some form of steel. For concrete bits, the shaft still has flutes to remove material and it generally feels just like using a standard steel bit. You don’t have to change the way you work just to use a carbide bit.

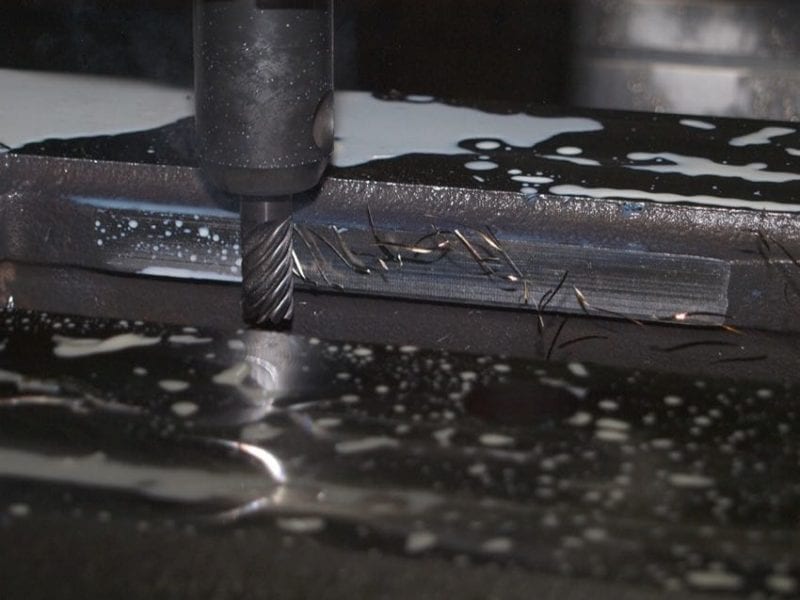

When it comes to CNC machines and extensive metal cutting, carbide plays a much larger role. Those bits often feature solid carbide throughout much of the cutting surface.

What Makes Tungsten Carbide Popular in Power Tool Accessories?

There’s a perception that accessories using tungsten carbide perform better than non-carbide ones. But does that perception match reality?

In most cases, it does. Carbide tooth blades outperform and last longer than steel or bi-metal in nearly every application. That combination makes it the go-to standard for the best miter saw blades and rotary hammer bits. It’s also gaining more traction for reciprocating saw blades and oscillating tool blades, too.

In terms of raw speed, some tasks benefit from standardized blades. In particular, steel reciprocating blades may cut more quickly in certain materials. Since they can optimize the teeth geometry to the material and avoid the wider kerf sizes, steel blades often beat wider, slower carbide-toothed blades. You also can’t beat the price of a cheap steel reciprocating saw blade. If you don’t intend to cut anything but wood or PVC, a steel blade works great.

Cheap vs Quality Carbide

The quality of the carbide has everything to do with the quality of the raw materials and the processes of shaping and attaching the material to steel.

Cheap carbide is more brittle and easier to chip. In the case of poor attachment processes, it can pop off entirely. Use a cheap carbide bit, and there’s a good chance you won’t buy another one.

Just don’t blame the entire material—often you just need to buy from a more reputable manufacturer. We’ve found excellent products from all of the major players including Bosch, Milwaukee Tool, Freud/Diablo, Lenox Tools, and others.

Tungsten Carbide Bits Cost vs Life (Durability)

Labor is the biggest cost on any jobsite and the bane of your existence is downtime—paying people when they’re not working. Your tools need to be ready to go and you need replacement accessories on-site to minimize downtime. Productivity comes to a halt and your client isn’t happy about the lack of progress.

One of the major benefits of tungsten carbide accessories is that it keeps everyone working longer. Since carbide provides superior speed for many accessories, the work moves along faster as well. Faster work is less fatiguing and less fatigue means higher quality work.

If that’s not enough, look at some of the claims on carbide blades. 10x, 50x, even 75x the life over standard ones? They may cost more upfront, but when you look at the cost per cut or per hole, they’re saving you money over the course of the job.

The Bottom Line

At the end of the day, tungsten carbide accessories are worth it when the heat doesn’t kill it, cutting edges don’t break, and tough materials don’t wear them down. When you buy carbide bits that use quality materials and manufacturing processes, they’ll outperform and outlast any standard ones you might have used before.