We love to review knives, particularly EDC folding knives, but everyone has their preference. There’s blade material, handle material, size, weight, and of course features. One thing that seems to be elusive, however, is the purpose of knife blade shapes. There are a lot of available knife blade shapes, and we wanted to pen an article to go over a few of the most popular. Having already covered knife blade grinds, this seemed like the next thing to tackle to help explain the various options available to consumers.

Straight Back Knife Blade

You’ll see a lot of straight-back knives because they are extremely strong. They are particularly popular for survival-style knives (in addition to the tango blade). Because of the way the tip of the knife is along the strong back of the knife, a straight back knife is good for driving forward into the material. It’s also excellent for slicing since the majority of the blade is simple to maintain along a cut line. The blades are also typically easy to sharpen since they only have a single curve along the front. A clip point knife is similar to a straight back knife except that the unsharpened back edge of the knife stops about halfway down the blade before dipping to the point in a curve or direct line. Because of this, the clip point knife is not as strong at the tip.

Drop Point Knife Blade

I’ve owned a drop point blade knife more than any other knife. This is the style of the Kershaw Blur knife, the Benchmade 580 Barrage knife, and also the CRKT Shenanigan knife. Like the straight-back knife, a drop point blade is great for slicing and is typically easy to sharpen (as far as the shape influences that). Where it differs is that the unsharpened back of the blade drops down to the point instead of remaining flat across the top. These knives have varying degrees of “belly”, and you will see lots of variations on this—often referred to as a “modified drop point”. You have a lot of cutting control with these knives, and they’re simple to control without cutting too deep when slicing.

Tanto Knife Blade

Most guys love the look of the tanto knife blade. What defines this blade is the hard break from the bottom blade to the front section. An “American Tanto” knife blade has a straight front edge while a “Japanese Tanto” knife blade will add some curve to that front edge. These knives are very popular for use as tactical weapons because of their strong tip and excellent ability to drive straight through tough material. You probably don’t want to skin anything with these, however, as you only have that small front part of the blade to slide across the material. Two popular knives we reviewed with this style blade would include the CRKT M16-12ZER EMT and the Kershaw Kuro 1835TBLKST.

Sheepsfoot Knife Blade

The sheepsfoot blade is named after its shape—which vaguely resembles one half of a sheep’s cloven hoof (viewed from the top). Because it has more of a flat front, it’s very difficult to pierce anything with this blade—making it great for rescue use or situations where you need to slice something without penetrating the material. A sheepsfoot blade also has a nice amount of surface area across the top and front, so you can grip it while using it and operate it with a good degree of control. You’ll see a lot of Japanese kitchen knives use this style of blade. It’s also about as close as you can get to a razor blade, making it great for opening up boxes and slicing through stiff cellulose material. The Byrd Rescue 2 and Spyderco Atlantic Salt knives we reviewed have a sheepsfoot design but with serrated edges.

Wharncliffe Knife Blade

The Wharncliffe blade is in the family of the sheepsfoot blade but with a more gradual decline towards the tip. This gives it a slightly more penetrating point, but it’s still a good knife if you want to do cutting without much chance of forward penetration. The Wharncliffe also maintains the lack of “belly” on the blade, so it’s not the best type of knife if you want to slice in a “fillet” style (the tip will drag and do most of the work). There’s a lot of debate as to the origin of the Wharncliffe blade and name, but in either case, the name is a relatively modern one as far as history is concerned. We reviewed the Kershaw Needs Work knife which has a distinctive Wharncliffe blade.

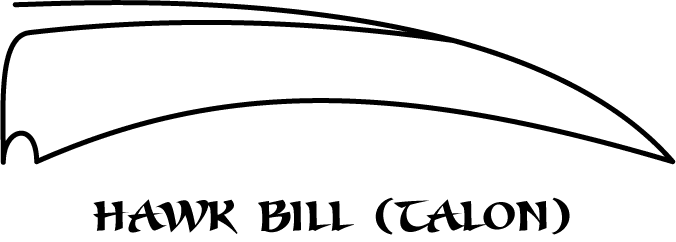

Hawk Bill Knife Blade

There’s no shortage of fascination with the hawk bill blade design. Similar in family to the carpet knife, the hawk bill blade does its cutting by pulling along the material. It requires very little downward pressure to work, allowing you to simply pull along in a direction with one hand. It’s also not good at stabbing since the point faces downward. To be honest, unless you’re cutting linoleum or doing some pruning, this knife is really a brutal combat-style knife that’s reminiscent of an animal’s talon or claw (hence the nickname of talon blade). A great example of a hawk bill knife is the Milwaukee Fastback hawkbill knife which we previewed—perfect for cutting back cable insulation or slicing through the cellulose. The SOG contractor knives also include a nice folding hawk bill knife for slicing through construction material.

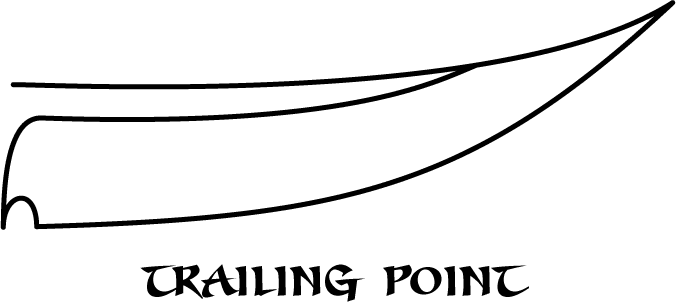

Trailing Point Knife Blade

The trailing point knife is basically a fillet knife. It has a very smooth, gradual belly that makes short work of slicing along surfaces or separating thin materials. All skinning or fillet knives are trailing point blades. The biggest defining characteristic is the tip, which actually pitches back upward beyond the back of the blade. While the point is sharp, it’s not the focus of this blade and may be its weakest…well, its weakest point.

Conclusion

There are certainly other types of blades, including the spear point, dagger, and all manner of interesting blade styles from China, Nepal, Japan, and other cultures. The above blades, however, are the ones you’re most likely to encounter when making a typical purchasing decision. Familiarizing yourself with these will give you leg up in understanding the very things that make each blade unique and effective for whatever tasks you may wish to use them.