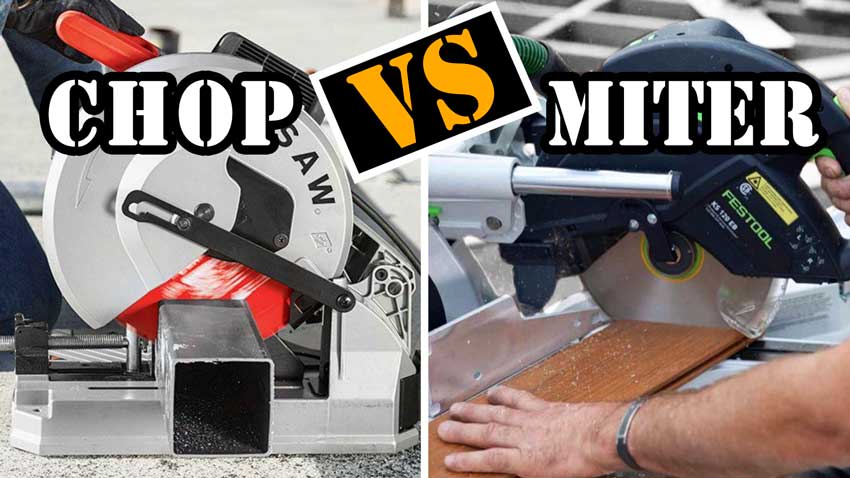

In looking at a chop saw vs a miter saw, we can quickly see these are two very distinct tools. They not only serve different purposes (metal-cutting vs wood), but they also function very differently from one another.

Despite this, we can’t tell you how many times we’ve heard the term “chop saw” used to describe a miter saw. It’s not a huge deal, but we always try to educate our readers (and those new to the trades) about the differences.

In this article, we’ll go through the various pros and cons as well as the differences, strengths, and weaknesses of each of these tools. If you’re more interested in the types of miter saws (compound, sliding, etc) we have an article on that as well.

Key Differences Between the Chop Saw vs Miter Saw

Possibly the best way to understand the chop saw vs miter saw is to simply cover the key differences. But first, let’s talk about what makes these two types of saws similar.

Both tools primarily allow for cross-cutting of material. Miter saws and chop saws both have a back fence to hold material while cutting and may also offer clamping systems to help stabilize material for cuts.

Both use a circular saw blade with an exposed bottom cutting edge that spins away from you. Regardless of which one you use, you need to keep your hands a minimum distance away from the cutting blade for safety.

Now, let’s look at some key differences.

Chop Saw Features

- Designed to cut metal (steel, aluminum, etc)

- Makes straight cuts with a blade that does not bevel

- Makes miter cuts by change the angle of the material

- Typically use abrasive, diamond, or carbide cutting wheels

- Blade sizes up to 15-inches (12–15 inches typical)

- Usually includes a clamp to hold material

- Can be high-speed (abrasive or diamond) or “cold-cutting” (carbide)

Miter Saw Features

- Primarily designed to cross-cut wood (trim, framing lumber, etc)

- Can be calibrated for high-precision cutting

- Makes straight or beveled cuts with a blade that also miters

- Makes miter cuts by changing the angle of the blade

- Uses carbide tooth blades

- Uses different blade tooth counts to change the cut finish quality

- Blade sizes up to 12-inches (7-1/4 to 12 inch typical)

- Usually includes a table clamp for holding material

- Can include extension wings for additional support

Chop Saws vs Miter Saws for Metal – Hybrid Miter Saws!

If you plan to cut a lot of metal at angles, you may have a tougher decision. When looking at chop saws vs miter saws for metal, we tend to gravitate towards anything that can help us use a carbide-tipped “cold-cutting” blade. That brings us to the topic of hybrid metal- and wood-cutting miter saws.

Some companies, like Evolution Power Tools, offer saws designed to cut both metal and wood. These tools use blades (or have multiple blade options) that handle both materials fairly well.

A typical hybrid saw more closely resembles a compound sliding miter saw than a chop saw. The “hybrid” functionality has more to do with the slower blade speed and the blade itself.

A hybrid saw often functions similarly to a cold-cut saw in that it uses a slower blade speed—well under the 3500 RPM we see on chop saws. That slower blade speed means it can use a carbide-tipped metal-cutting blade and doesn’t require an abrasive or diamond wheel like high-speed saws.

Chop Saw vs Miter Saw Blades – Abrasive, Diamond, and Carbide

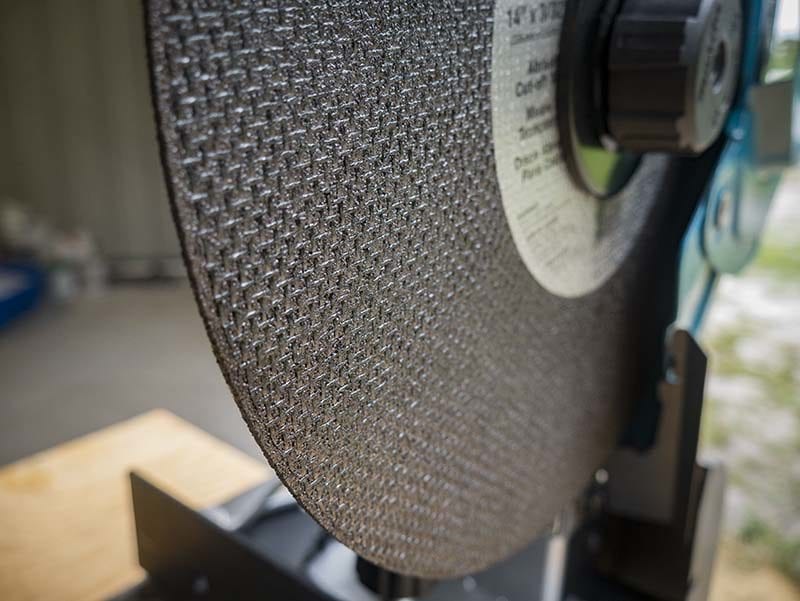

Chop Saw Abrasive Cutting Wheels

Most chop saws use abrasive metal-cutting blades. There are many reasons for this, but the main reason is that these blades are inexpensive, and they get the job done.

Abrasive blades offer consistent, though imprecise, cutting of most soft steels. They really tend to have difficulty making more precise miter cuts since they inherently deflect and flex during use.

Don’t use a standard abrasive cutting disc on aluminum, either. The soft aluminum will quickly gum up the wheel’s edge and render it useless.

Chop Saw Diamond Cutting Wheels

Chop saws designed for abrasive wheels aren’t compatible with slower-speed (RPM) saws that use carbide-tipped blades for cutting various metals. You can find some steel blades designed for higher-speed saws.

One example is the Milwaukee Steelhead Diamond cut-off blade. It uses exposed synthetic diamond grits along the cutting edge. We also don’t recommend using a blade like this one on aluminum. For that, we’d opt for a slower saw with a carbide blade.

Chop Saw Carbide Tooth Blades

Cold-cutting chop saws, which use slower RPMs to cut metal, have a variety of carbide-tipped cutting blades. These blades resemble traditional wood blades, but they are optimized for cutting steel more safely. Some also prioritize softer metals like aluminum.

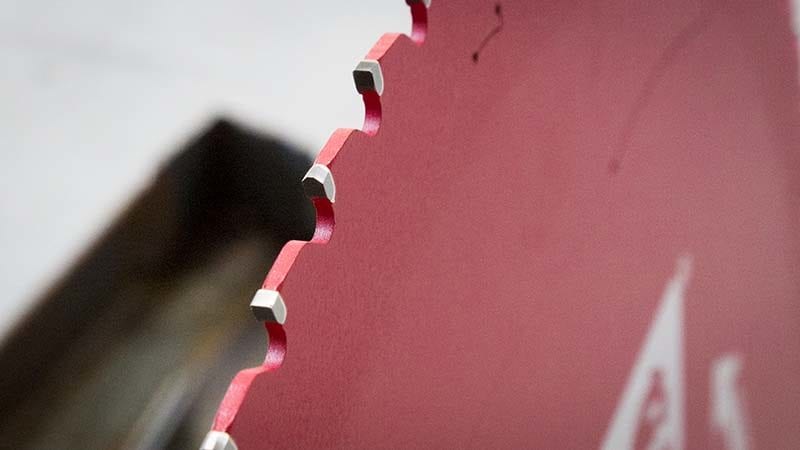

Miter Saw Carbide Tooth Blades

Nearly every miter saw blade available has carbide teeth. While they appear similar to the carbide blades of cold-cutting chop saws, there are significant differences.

The tooth rake angles and gullets have different shapes and sizes. For premium blade manufacturers, even the carbide blend itself may have differing chemical compositions and/or attachment techniques to match the job it’s going to do.

One big feature of miter saw blades is the tooth count. You can use lower tooth count blades for faster cutting with a rougher finish. On the other hand, a high tooth count blade cuts slower but has a finer finish. Some even have so fine a finish that the wood doesn’t require any sanding before you install it.

While chop saw blades can have varying tooth counts, it’s more about the type of material it’s cutting rather than the quality of the finish.

Chop Saw vs Sliding Miter Saws

We’ve addressed beveling in our discussion of the chop saw vs miter saw decision. One thing yet to be addressed has to do with capacity or depth of cut. Most metal chop saws deal with cross-cutting short pieces of metal 4-inches or smaller.

If for some reason, you need to cut larger pieces of metal, you might think a sliding miter saw could offer a solution. While technically true, the better solution might be a handheld metal-cutting saw like the Milwaukee cordless metal cutting saw.

With larger cross-cut lengths, you want to be very careful when using a tool like a miter saw to cut metal. A dedicated metal saw creates a much safer situation when making longer cuts and affords you a better opportunity to secure the piece while cutting.

Chop Saw vs Miter vs Hybrid Saws Compared

We also put the above (and more) into a table for easy observation:

| Chop Saw | Miter Saw | Hybrid Saw | |

|---|---|---|---|

| Possible cut types | Cross cuts (90°) | Straight, bevel, miter, compound | Straight, bevel, miter, compound |

| Square material capacity | up to 4-3/4 in. | around 4 in. | around 4 in. |

| Round material capacity | up to 5-1/8 in. | N/A | up to 4 in. |

| Rectangular capacity | 4 x 7-5/8 in. 2-3/4 in. x 9-1/8 in. | up to 2 x 12 in. | up to 2 x 12 in. |

| Blade sizes | 12–15 in. | 7-1/4 to 12 in. | 10–12 in. |

| Types of blades | abrasive, diamond, carbide | carbide | carbide |

| Blade speed | fast or slow (cold cut) | fast | slow |

| Material it can cut | steel | wood | steel, aluminum, wood |

| Weight | heavy | lightweight to heavy | lightweight to heavy |

Final Thoughts

We can’t possibly hit every conceivable topic related to the chop saw vs miter saw question. Once you understand the various issues, like cutting speed, capacity, and the type of material and cut, you should be better equipped to make an informed choice.

We can’t emphasize enough the need to pay close attention to blade speed. Don’t put a low-speed metal blade on a high-speed saw in an attempt to convert your tool, or vice versa. Rather, look for a blade that matches the speed of your saw for safety and efficacy.