Bay-Lynx Titan Gets Complete Redesign

Bay-Lynx has just announced the newest edition to its line of construction equipment, the Titan Volumetric Concrete Mixer. The redesigned Titan, Bay-Lynx promises, is stronger, lighter, and smarter than your current options.

10-Second Summary

- Titan uses Hardox 450 steel extensively in its construction

- 200% service life, 1200 lbs additional payload, 15% higher resale value

- BatchPro Connect interface can control and automate mixing functions

- BatchPro Connect software includes customer order portal, dispatch platform, and mobile app

How is the Bay-Lynx Titan Better?

One of the primary features of the Bay-Lynx Titan redesign is the use of Hardox 450 steel in the construction of the mixer. According to the company, Hardox is some of the strongest steel available, adding to the mixer’s overall durability, strength, and resale value. Bay-Lynx boasts that the Titan, by virtue of the Hardox steel used so extensively, has a 200% longer service life and has a 15% higher resale value than volumetric mixers that use mild steel.

Editor’s Note on Hardex 450 Steel: Hardox 450 is an abrasion-resistant steel with a nominal hardness of 450 HBW. Hardox 450 combines good bendability and weldability with an option for guaranteed impact toughness (Hardox 450 Tuf). The products can be used in many different components and structures that are subject to wear. Hardox 450, with an extra 50 Brinell hardness over our 400 grade, provides better dent and abrasion resistance as well as longer wear life, so you can achieve even greater savings. [Source: SSAB website]

Also, because the Hardox steel and redesigned frame account for a 1200 lb weight savings, the Bay-Lynx Titan can carry a much greater payload.

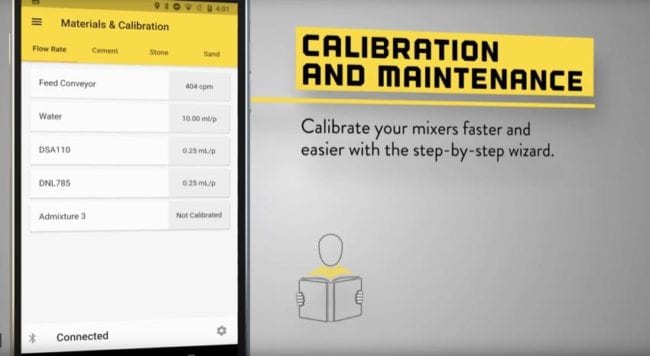

Next, the Bay-Lynx Titan Volumetric Concrete Mixer features some of the most advanced mixing technology on the market. The BatchPro Connect interface lets stone, cement, water, and admixture content be controlled and automated using the BatchPro 3.0 panel.

You can even adjust your water content on the fly, based on the moisture content of your aggregate.

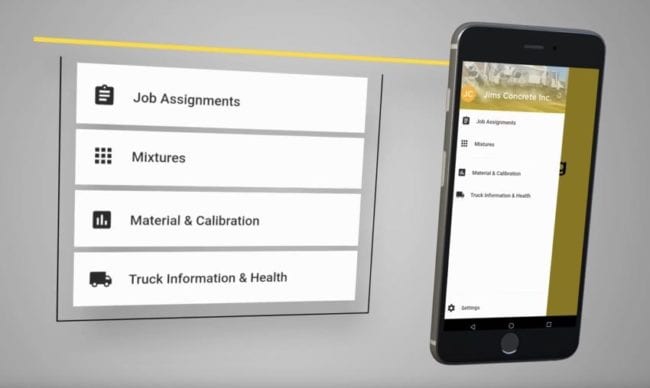

The BatchPro Connect software also includes a customer order portal, a dispatch platform, and an operator’s mobile app.

Bay-Lynx Titan Volumetric Concrete Mixer Features

- 1900 L Water Tank

- Hardox Aggregate and Cement Bin

- Automated Admix System

- Hydraulic Cement Drive

- Lightweight Auger Frame

- Easy-To-Use Operator’s Panel, Including BatchPro Connect Software and Automation

- Automated Hydraulic Gates

- Moisture Meter for Automated Moisture Adjustment

You can explore the Bay-Lynx Titan even further by clicking here.