Battery technology usually doesn’t fail on a spec sheet—it fails on the jobsite. Drops, heat, vibration, high current draw, and repeated fast charging do far more damage than most lab tests account for. Self-healing batteries are often discussed as futuristic science projects, but recent research suggests some of these ideas may eventually help batteries survive the kind of abuse power tools deliver every day. This article looks at where self-healing battery technology really stands, what parts might actually matter for tools and EVs, and what’s still firmly stuck in the lab.

Table of Contents

- What the Research on Self-Healing Batteries Really Means

- Why Tool Batteries Actually Die

- Self-Healing Electrodes: Maintaining Power Under Load

- Electrolytes That Recover Instead of Failing

- Interfaces: The Silent Performance Killers

- It May Be a While Before You See “Self-Healing” on a Battery Label

- What This Could Mean for Power Tool Brands

- Bottom Line

What the Research on Self-Healing Batteries Really Means

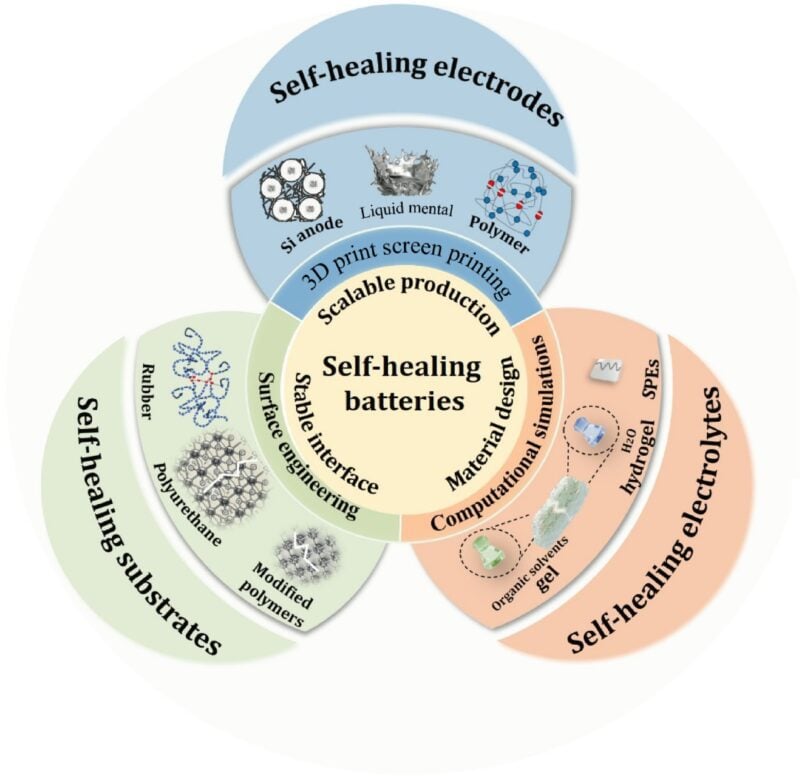

The idea of a “self-healing battery” sounds almost too good to be true. A battery that repairs internal damage on its own could, in theory, last longer, stay safer under abuse, and maintain performance instead of slowly fading away. Researchers have been exploring this concept for years, but a 2025 research review shows the field moving beyond novelty and into more application-focused work.

That doesn’t mean you should expect a self-healing battery pack on the shelf anytime soon. What it does mean is that some of the underlying ideas could quietly influence future power tools and EV batteries—without ever being labeled as “self-healing.”

Why Tool Batteries Actually Die

Most power tool batteries don’t fail because of a single dramatic event. Instead, they lose performance gradually. Runtime drops. Tools bog down sooner under load. Packs get hotter than they used to. Eventually, a battery that still technically works ends up relegated to light-duty tasks.

Inside the cell, this decline often comes down to mechanical damage. Electrodes crack as they expand and contract. Conductive pathways break. Interfaces between materials lose contact. High-draw tools like cordless grinders, drills, and saws accelerate this process through repeated current spikes and heat cycles, while drops and vibration add physical stress that lab testing rarely replicates.

Self-healing battery research focuses on these exact failure modes—not on increasing capacity, but on keeping the internal structure intact longer.

Self-Healing Electrodes: Maintaining Power Under Load

Silicon-based anodes can fracture internally as they cycle. Therefore, finding out how to make electrodes that tolerate cracking by automatically reconnecting is a huge area of interest. Researchers are currently experimenting with flexible binders and dynamic materials to let cracked particles reestablish electrical contact where they would otherwise become permanently isolated and fail.

When using power tools, a cracked electrode can produce a drop in voltage while under load. Practically, that would cause a drill or impact driver to lose its maximum amount of torque or speed, or even cause a circular saw to slow down when cutting thicker sheet goods and 2x material. However, if a battery can maintain (or repair) its internal connectivity, it would deliver more consistent performance across its lifespan—even if the total capacity of the pack remained consistent.

We can apply the same principles to EVs—just on a larger scale. Reduced internal cracking in cells could slow long-term degradation and help those larger battery packs maintain their fast-charging capabilities, even over many years of use. As these packs represent the large portion of a vehicle’s cost, we want them to function optimally for as long as possible.

Electrolytes That Recover Instead of Failing

Electrolytes are the medium used in a battery to conduct ions from the positive and negative electrodes. Needless to say, they play a major role in how batteries age. Having an issue with your electrolytes is like trying to drive a car over a large pothole or cross a deep chasm that’s bisecting the road. Some up-and-coming self-healing designs use electrolytes composed of either polymers or gels. The point is that they feature “reversible” chemical bonds. That means that when any sort of mechanical damage breaks the flow of ions, the bonds can reform. It’s as if the crack or pothole in the street is able to repair itself… which, come to think of it, would possibly be an even greater advancement than self-healing batteries.

In looking at power tools, this has a lot more to do with reliability than performance. Batteries that can survive drops, vibration, thermal shock, or even minor punctures without developing internal shorts or hot spots could see fewer early failures. For EVs, this would greatly improve safety margins—particularly when using higher current (fast) charging modes.

The catch here is durability. Self-healing systems need to do so repeatedly over thousands of cycles—not just once in a lab demo. After healing, they need to continue operating at the same levels of efficiency and capacity across wide temperature ranges.

Interfaces: The Silent Performance Killers

Some of the most critical battery failures happen at the places where different materials make contact, such as where electrodes meet current collectors or electrolytes. When those contacts degrade, resistance rises, and heat follows.

Self-healing interface layers aim to maintain contact by reorganizing themselves after damage. This is particularly relevant for next-generation EV batteries and solid-state designs, where rigid interfaces are already a known area of weakness. While this research is still early, it targets one of the most common reasons batteries lose efficiency long before they lose capacity.

It May Be a While Before You See “Self-Healing” on a Battery Label

Despite the progress, self-healing batteries aren’t yet ready for primetime—not for tools or for EVs. Aside from ensuring long-term performance and durability, healing mechanisms add cost, complexity, and even reduce energy density. That makes them a trade-off that will make sense in some scenarios, but not in others. Additionally, few have shown that they can survive the extreme duty cycling and abuse that professional tool users demand. This also holds true for the near-constant cycling demands of large EV packs.

That’s why the most realistic outcome isn’t a fully self-healing battery, but partial adoption of the ideas behind it. We are more likely to see power tool and EV manufacturers integrate tougher binders, more forgiving interfaces, or mechanically tolerant designs—all without ever advertising them as “self-healing.”

In other words, the benefits may show up in batteries that simply age better.

What This Could Mean for Power Tool Brands

Taking the above into account, self-healing research will most certainly influence power tool batteries, though the advances may occur over time and with little fanfare. Specific improvements may look like:

- Battery packs that maintain performance longer under higher loads

- Reduced early failures from vibration, drops, or heat (either environmental or from extreme usage)

- More consistent power output over a battery’s usable life

While that’s less exciting than “[your favorite tool company] introduces self-healing batteries!”, it’s the kind of improvement professional contractors, landscapers, and mechanics will appreciate and recognize over time. Anything we can do to reduce the number of battery replacements in a company, crew, or fleet means less downtime and lower operating costs.

Bottom Line

Self-healing batteries aren’t about making tools more powerful—they’re about making batteries more resilient. Today’s research suggests real progress, but it also presents realistic limitations. That means you shouldn’t wait for self-healing batteries before buying your next power tool or electric vehicle.

Instead, think of self-healing battery research as part of a broader trend. It will likely yield batteries designed to survive real use, not just pass lab tests. If those ideas continue to mature, the biggest win won’t be a new buzzword—it will be batteries that maintain performance and capacity years down the road.