New technology is yielding more powerful cordless outdoor power equipment and tools. One new type of motor being integrated into power tools is the outer rotor brushless motor design. Also called outrunner motors, we’ve seen these used on everything from cordless circular saws to battery-powered chainsaws, string trimmers, and lawnmowers. So, what is an outer rotor brushless motor and how do inrunner vs outrunner motors differ?

We spoke with Carlos Quintana, Senior Product Manager of Makita’s Cordless Tools division to get an idea of the difference along with the pros and cons of both designs.

Be sure to also check out our general article on Makita brushless motors.

Table of Contents

General Design Differences in Outer Rotor Brushless Motors

The main difference between inner rotor and outer rotor brushless motors lies in the basic design. All brushed or brushless motors use magnets to turn. The role of the stator is to provide a charge that will repel or attract the magnets and make the motor spin. The rotor contains those magnets and does the spinning.

On an inner rotor design, the stator is on the outside and the rotor is on the inside. On an outer rotor brushless motor, they flip.

Inrunner vs Outrunner Motors Footprint

Let’s say you have one of each type of motor with identical power outputs and overall diameters. How to do they look compared to each other?

Comparing the inrunner vs outrunner, you find both have the same magnetic surface area. Since the inner rotor design has the magnets against the inside, they’re on a smaller diameter – they will need to be longer.

The opposite is true on an outer rotor brushless motor. Attaching to a wider diameter means you can shorten the overall motor length. Also, you get a natural weight reduction.

Outer Rotor Brushless Motor Efficiency

Inner rotor motors also have an inherent wobble. They ride in and out slightly within the stator and lose efficiency. There are ways to deal with that, however. For example, Makita adds ridges to help stabilize their rotors and bring the efficiency up to 99%. But not all motor manufacturers do that.

Outer rotor brushless motors don’t have to deal with that movement and are inherently more efficient by design.

Balancing the Benefits of Each Design

So you end up with two choices when you go with an outer rotor design. One option shrinks the length and weight of the motor to get the same power with a bump in efficiency.

Alternatively, you can maintain the weight and achieve more power with those efficiency gains. Of course, you can also find a balance between the two and shave some of the weight while increasing the power on a less substantial level. We really see this with battery-powered weedeaters which can benefit from the reduced weight of front-loaded brushless motors.

Comparing outer rotor (outrunner) brushless motors against inner rotor (inrunner) designs, we can see how each typically leads in various categories.

| Outer Rotor Brushless | Inner Rotor Brushless | |

|---|---|---|

| Overall Diameter | Wider | Narrower |

| Overall Length | Thinner | Thicker |

| Torque | Higher* | Lower* |

| Efficiency (including speed and power usage) | Lower | Higher |

| Heat Dissipation | Lesser | Greater |

| Typical Tool Usage | Larger Tools (mowers) | Smaller Tools (drills) |

Inrunner vs Outrunner Applications for Power Tools

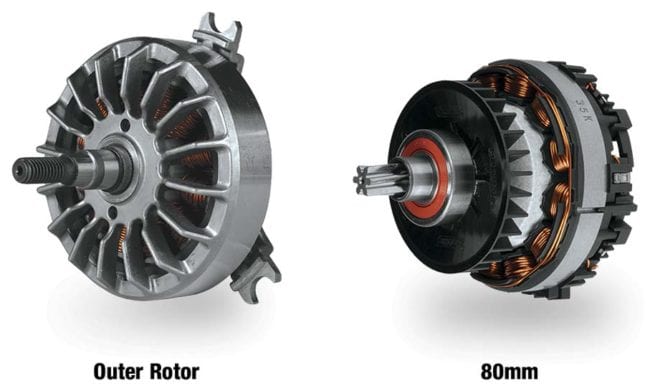

The majority of brushless tools utilize an inner rotor design to cut down on overall size (girth). Makita uses at least four brushless inner rotor designs: 80mm, 54mm, 44mm, and 38mm.

The Makita 18V X2 string trimmer and its chainsaws get a fifth design with an 80mm outer rotor brushless motor. These larger tools have room to house the motor’s larger diameter while finding relief in the overall footprint since they have a narrower length.

That profile allows Makita to put the motors in those tools with a direct drive so they get the benefit of the most efficient power transfer.

Looking Forward to More Outer Rotor Brushless Motor Tools

As manufacturers look to drive more traditionally corded tools to cordless, you can expect to see more outer rotor brushless motors. Lithium-ion still hasn’t reached the pinnacle of its capabilities. Outer rotor designs help generate more power and efficiency as we push the limits of what battery power can achieve.