Rounded-out screws got you down? We’ll show you how to use a screw extractor to remove damaged screws. Do it right, and you can back a busted screw out of its hiding place in less than a minute. Of course, you need the right tool.

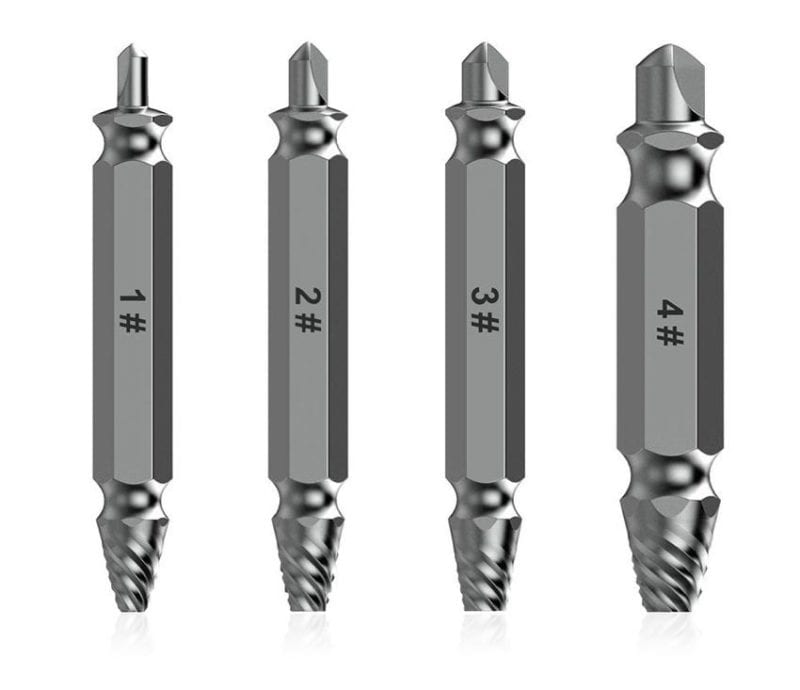

A good screw extractor design uses a tapered drill bit with reverse threading. You spin the bit in reverse as if to back out the screw normally. Because of the reverse threading, it bites down into the head of the stripped fastener while backing it out. Maybe it’s not so much how to use a screw extractor as it is choosing a reliable product to get the job done.

Editor’s Note: Check out our best deck screws article to see our top picks.

Table of Contents

Using a Screw Extractor: The Cliff Notes

- Use a set with double-ended boring/screw extracting bits—they’re easier

- Look for hardened steel—these bits need to be strong

- Using your drill in reverse, slowly bore out the damaged head

- Flip the bit around and use constant pressure in reverse (slooooooow speed) to drive in the extractor until it bites

- Slowly keep turning the screw/bolt/plug out until it works free

Why Do I Need a Screw Extractor?

Sometimes you can cut or bend off a fastener and it’s fine. Other times, however, you’ve simply got to get it out. Rounded out and stripped screws can throw a real wrench in your productivity, but they don’t have to bring your work to a grinding halt. Keep a relatively inexpensive screw extractor on hand. It will let you quickly remove those pesky worn and weathered fasteners with a minimal amount of frustration.

Any Pro from mechanics to woodworkers should keep a set of screw extractors close by. If you’re just starting out, or you find yourself apprenticing with a Pro, we can show you how to extract a screw as if you’ve been doing it for years.

How a Screw Extractor Removes Damaged Screws

The key to the screw extractor’s usefulness lies in its general design. While brands vary, the most common design uses a tapered drill bit with reverse threading. This helps it lock into and remove damaged screws. Makes sense, right?

Basically, after punching or drilling into the top of your busted-up screw, you’ll use a screw extractor to bite down into the screw and twist it back out of whatever it was holding together. Easy-peasy.

How to Use a Screw Extractor – Step by Step

Step 1: Gather Some Needed Tools

You need a few tools depending on the type and size of fastener as well as the material you’re trying to remove it from:

- Screw extractor

- Hammer

- Center punch

- Drill (we do not recommend using an impact driver—too much torque and speed)

- Drill bits (not needed if your extractor has a boring end)

- Thread cutting oil and/or penetrating oil

- Wrench

- Safety glasses

Step 2: Safety First

Don those safety glasses, because your work could potentially send a few metal shards flying about. You always want to protect your eyeballs from debris. You may also want a pair of gloves if you’re concerned about metal shavings cutting you.

Step 3: Punch It Out

With a basic screw extractor, you may need to provide some space in the screw head for it to work. That means drilling or expanding a hole in that old screw.

To do this, you align a punch to the center of the screw and hammer it down lightly. This will create an indentation in the very center of the screw that will help guide the drill bit.

Some screw extractors have a burnishing end that you can use to drill out the screw head directly. If that’s the set you have, skip the punching and drilling step.

Pro Tip: If you’re working a bolt or plug out of an engine, mind those metal shards – you don’t want them falling into the engine block!

Step 4: Drilling a Guide Hole

Next, find a drill bit that has a smaller diameter than the screw you need to remove. To make your life easier, add a little bit of thread cutting oil to the head of the screw. This goes a long way.

Keeping your drill bit straight, drill down slowly into the screw. Depending on the size of the screw extractor you plan to use, you probably only need to drill down about 1/8″ to 1/4″.

Pro Tip: Take your time. If you’re stopping to remove a screw, then there’s some value in protecting your workpiece. Don’t ruin the whole thing by rushing the process. You also want to use a drill for this process as the mechsnism on an impact driver doesn’t deliver a smooth action.

If you’re using a burnishing/extractor double-ended bit, you’ll need to kick your drill into reverse to use it properly. The nice thing is that the double-ended bit already matches up with the proper extractor size, so there’s no guesswork. Just compare each bit to the screw and choose the best size.

As you can probably tell, we find double-ended screw extractor sets easier to use.

Step 5: Screw It

For a tutorial on how to use a screw extractor, it feels like we took a long time to get to the actual screw extraction, doesn’t it? Well, here we are. At this point, you can finally put the screw extractor to use.

If you’re using a drill in reverse, turn the screw extractor into the guide hole you’ve drilled. The screw extractor will twist down until it grabs hold of the screw. Once that happens, just keep turning until your screw is safely out. Go very slow.

Pro Tip 1: If the screw extractor doesn’t bite, drill or bore out a little more of the head. Most screws will only require 1/16″ or so to work, but you might need to go a little further on some. If it still doesn’t work, try the next size up.

Pro Tip 2: Consider manually running the extractor out. Using a drill in slow speed will work, but more than a few times we’ve broken bits by running them too quickly into a truly stuck fastener. The larger and “stucker” the fastener, the more likely a manual approach will work better than your drill.

Final Thoughts

The biggest issue with extracting screws might simply be having the right tools for the job. We’ve tested a couple of solid products we like including the Gearwrench Bolt Biter screw extractors. Check those out if you haven’t already—and see the products listed at the bottom of this article for more recommendations.

If you have any other tips and tricks on how to use a screw extractor, feel free to leave a comment in the section below.

Rockler has a really good video explaining both how a screw extractor works and which takes you through the process. You can watch it here.