Hi, my name is Jon and I am addicted to air sanders…About four years ago, while looking for a 12-step program or support group for my problem, I ended up purchasing a large compressor to support my habit of powering a few sanders at a time. I was committed; I piped my whole shop with air lines and hose reels. There was no turning back. This review aims to see if the Festool LEX 3 air sanders can stave off the onslaught of the electric competition.

Air sanders are low profile, lightweight, have less vibration than their electric counterparts, and when properly cared for, they’ll last forever (no motor to burn up). So, why are they such a rarity in American woodshops? Better yet, can the new Festool Lex 3 Air Sanders reverse the trend?

Why Pneumatic Sanders Don’t Get to Sit at the Cool Kids’ Table

The answer to my first question is any combination of a handful of significant drawbacks. First, compressors that can supply 10-15 CFM @ 90 PSI per sander can get expensive. Secondly, cooling that air enough to remove all the moisture can be very tricky without additional large expenses. Third, you have to oil the sanders to keep them running fast and lasting long, but it’s difficult to prevent that oil from misting onto your unfinished workpiece through the air exhaust on the back of the sander. Rarely do you want to oil all of your air lines in a woodshop, since duster nozzles are frequently used to clean off raw wood surfaces. Finally, dust extraction through most air sanders is sub-par and you lose out on “auto-on” features found on many dust extractors when used with electric sanders.

For me, the benefits of using air sanders still outweighed the drawbacks. I was running sanders from Dynabrade, Ingersoll Rand, and DeWalt to cover all my bases. Having made custom modifications to address each issue (aside from the auto-on feature), I knew there had to be something better.

I knew Festool sold air sanders but wasn’t sure the North American Festool Lex 2 sanders would be a good fit for the way I do things. When I came across the lower profile Festool LEX 3 Air Sanders on Amazon, and re-read the “3-in-1 Hose Connection” bullet points, I decided to dig into the parts again. It seemed as though Festool was providing a solution for every known drawback to using air sanders for woodworking.

Putting the Pieces Together

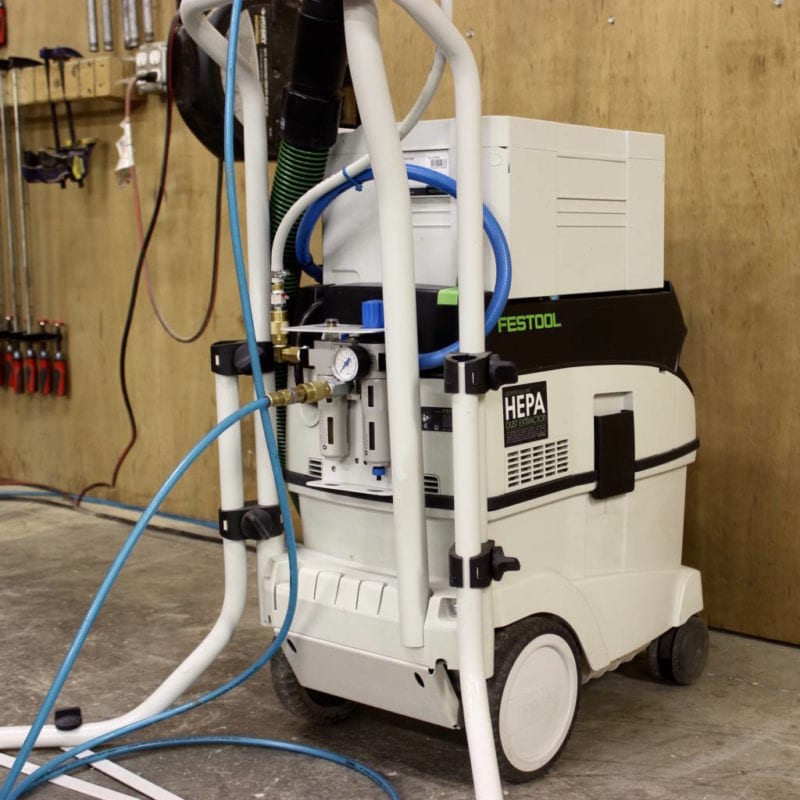

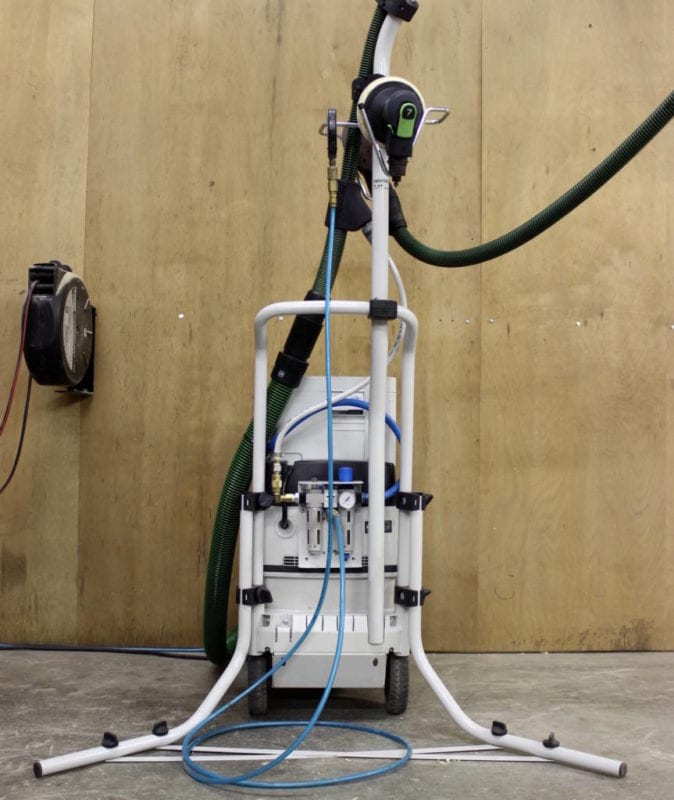

It may feel like your Festool CT Dust Extractor is up for a starring role in the next Transformers movie or just got selected for an episode of Pimp My Ride, but the add-on parts transformation will be well worth it. I’ll do my best to simplify the options and setup for the Festool CT 36 HEPA Dust Extractor that I use. Here’s what you’ll need and why you’ll need it:

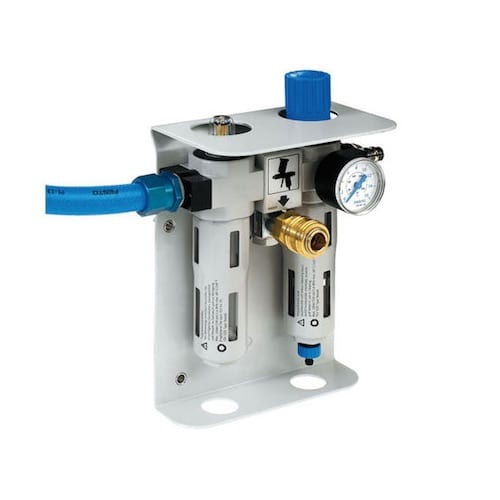

Service Unit – 495886

This is the regulator and oiler unit that mounts to your CT Dust Extractor. The pressure setting on your regulator will more closely match actual pressure at the sander the closer it is to the tool. Having the oiler at the dust extractor means you don’t have to have your entire air line oiled. There’s even a pre-oil coupler for plugging in a dusting nozzle. There are a couple of different part numbers for the service unit, so make sure to order the one that correctly fits your extractor model.

Compressed Air Module – 496141

The compressed air module is a key component of my Festool Lex 3 Air Sander system. This is what allows the Festool CT Dust Extractor to kick on and off automatically, activated by air flow through the lines. There are a couple of different part numbers for the air module, so make sure to order the one that correctly fits your extractor model.

IAS Hose System

The Festool IAS hose design allows for air supply, air exhaust, and dust extraction in one hose, with one simple 360º swivel connection point at the sander.

It. Is. Awesome.

Not only does Festool eliminate tangle between the air and dust hoses, they divert the oily air away from your work piece.

There are two options in the IAS hose system; IAS 2 and IAS 3. Both have the same connection at the tool, however the IAS 2 requires an adapter at the CT Dust Extractor and IAS 3 requires no adapter. The IAS 2 exhausts the air from the tool through the hose to prevent oil on the surface. By contrast, the IAS 3 exhausts air at the tool, yet without spraying oil droplets on your work surface. I went with the IAS 3 and can attest that it leaves no oil on the work piece. This newer hose is also lighter weight since an exhaust hose doesn’t have to run through the main hose.

CT Boom Arm Bundle Set – M0114

The boom is not a requirement, but I highly recommend adding it to the setup. The IAS hoses are a bit heavier than standard dust collection hoses, so it’s nice to have the boom arm to free you up from managing the hose around corners/edges. You can also really take advantage of the 360º swivel connection when the hose is kept off your work piece.

I’ll get more into the boom arm in part 3 of my series on Festool sanding systems, where I’ll focus on CT accessories and sanding workflow.

Conversion Notes

Festool is a German company and they don’t seem to sell much of the pneumatic line here in the U.S., so expect a little puzzle-solving during the initial setup. The European pneumatic couplers and plugs aren’t compatible with ours, plus they are threaded BSPT (British Standard Pipe Thread), which is a non-tapered thread, unlike our common NPT (National Pipe Thread). This combination requires switching out some of the fittings for those that work with what is found on US pneumatic tools and adding BSPT to NPT adapters to fit the threading properly.

Finding adapters here can be a challenge, but you will find everything you need at a hydraulics supplier. That sector lives and dies by BSPT fittings and I found my local guy to be incredibly helpful.

Using Festool Lex 3 Air Sanders

Festool Lex 3 Air Sanders are as close to ergonomic and performance perfection as I’ve experienced in one tool. I love the paddle switch on pneumatic sanders. It’s placement feels like you just hold the sander and it turns on – let go and it turns off. With the CT 36 in lockstep, I feel like a sanding magician! Hmmm, now that the boom arm is managing the hose, I have a free hand. Maybe I should get a wand…

Anyway, one of the unique features of the paddle switch is that although the LEX 3 air sanders have a variable speed lever, you can also manage your speed by partially releasing the paddle. Like a variable speed trigger, this makes it much easier to decrease the sander’s aggressiveness on the fly, when softening edges or sanding delicate areas of your work piece.

Festool also implemented a pad brake on the LEX 3 air sanders so you can set the tool down almost immediately after releasing the switch without accidentally scratching the surface by way of a spinning pad.

The three Festool LEX 3 models I’m using are the 150/7 (6”, 7mm course stroke), the 150/3 (6”, 3mm fine stroke), and the 77/2.5 (3”, 2.5mm fine stroke). The 7mm stroke on the LEX 3 150/7 makes it a very powerful sander – the most aggressive random orbit air sander I’ve used. It levels glue seams and removes material very quickly. With a fresh 100-grit sanding disc, it can feel a little jumpy for the first few seconds, but quickly settles into a smooth sanding pattern. I typically use the LEX 3 150/7 for grits of 100–150.

The LEX 3 150/3 is easily the smoothest and most consistent sander I’ve ever used. It has next to no vibration. Of the standard wood finish options at my furniture company, there are two where I purposefully sand an uneven/worn pattern into the wood after oxidizing it. The Festool LEX 3 150/3 is so smooth and sands so consistently that it’s difficult to get the achieve the distressed look I’m going for!

This sander has brought my clean/even toned finishes to a new level of perfection. It’s particularly noticeable how well it does on my hand-rubbed, white-tinted oil finish on ash that moonlights as a sanding scratch highlighter.

The LEX 3 77/2.5 is the perfect size to reach into those tight spots and recesses. It’s nice to just switch out the sander without having to get out one of my small electric “tight spot” sanders. There are still small areas that I’ll sand by hand, but those spots are fewer and farther between with this little guy at my disposal.

Festool LEX 3 vs Other Air Sanders

My mind always defaults to cars when trying to articulate the differences between two similar tools, so I’m going to run with it. Let’s say you need a 4-door sedan, but you love performance vehicles. My previous air sander setup was akin to purchasing a Honda Accord, changing out wheels, tires and brakes, upgrading the exhaust, tuning the engine, adding a cold air intake and bigger radiator, yada, yada, yada…

In other words, you might be able to push the limits and get specs close to a BMW M5 on paper, but it’s just not the same. One the other hand, the Festool Lex 3 Air Sander setup was just like buying the BMW straight from the dealer.

The Festool LEX 3 system was designed from the ground up with production performance in mind, and the result puts Festool in a completely different league. The increase in productivity and quality is significant and immediately noticeable.

Like a BMW, the improvement is not attributed to one single aspect of the system, but the system as a comprehensive experience. You’re simply not going to be able to match the Festool Lex 3 system with anything else, no matter how you customize it.

Festool LEX 3 Air Sanders vs Festool ETS EC Brushless Sanders

In Part 1 of my 3-part series on Festool sanding systems, I reviewed the new electric ETS EC Brushless Sanders. I hope it’s apparent from the article that I was thoroughly impressed with the performance and design. My Dynabrade air sanders have been living in the sander drawer at least 80% of the time since then, and the ETS EC sanders have taken over the primary sanding position.

I’ve been growing accustomed to their power and efficiency, as well as the simplicity of rolling around the CT Dust Extractor with the Workcenter attached to the top (more on that in part 3). Wherever I’m working, I just wheel the entire sanding station along with me – it’s very convenient.

By the time I received all my CT conversion accessories and my Festool LEX 3 Air Sanders, I had a really solid feel for the best electric sanding setup currently on the market (in my opinion, of course), as well as a good history of using very highly rated random orbit air sanders. A comparison between Festool’s electric and pneumatic systems had to be made.

I honestly feel like I have the two best sanding systems on the market in my shop, running simultaneously. There is no doubt the ETS EC sanders are very powerful, fast, well-engineered, and have great features. In comparison, Festool LEX 3 Air Sanders trade off some of that power for ergonomics. Air sanders aren’t for everyone, but if you’re willing to open your mind a bit, you might find that the pneumatic power blows away electric in some aspects – and they may just suit your needs perfectly. Here are my pros and cons for the two systems:

Festool LEX 3 Air Sander System

PROs

- Lightweight

- Smooth operation

- Paddle switch

- Fast tool change out

- Tangle-free 360º swivel hose

- Best finish sander I’ve used

CONs

- Requires large air compressor

- Expensive CT Dust Extractor conversion

- Not as aggressive as the ETS EC

Festool ETS EC Brushless Sander System

PROs

- Lots of torque / Fast material removal

- Better dust removal

- Easier to use with other tools (primarily routers and circular saws)

- Lower setup cost

CONs

- Heavier

- Longer tool change out time

- Hose and power cord get twisted

Final Thoughts

Festool LEX 3 Air Sanders certainly aren’t for everyone, nor are they for every woodshop. However, if you have plenty of air power and you do a lot of finish sanding at a production level, you’d be hard-pressed to find a faster, more comprehensive, and well-thought-out sanding system that will yield this high quality of a finish on a consistent basis – all while operating more smoothly than anything else on the market.

I’ve used and owned a lot of sanders, both pneumatic and electric, and even though the Festool ETS EC Brushless Sanders have a bit more torque and can sand more aggressively, the Festool LEX 3 Air Sanders are by far my favorite. I’ve found my holy grail and I’ll probably never change.