If you’re buying a miter saw, the sheer number of types, sizes, and features can quickly overwhelm you. When you’re investing in a precision cutting tool like this, it’s worth spending the time to learn as much as you can so you can make the most informed decision. In this article, we’ll walk you through the most important things to look for on a miter saw and arm you with more confidence in making your choice.

Ready to Buy? Check out our best miter saw article for our top recommendations.

Looking for Something Specific? Jump to these Sections

- Types of Miter Saws

- Chop Saw vs Miter Saw

- Battery Powered vs Corded Miter Saw

- Miter Saw Sizes

- Miter and Bevel Capacity

- Laser vs LED Shadow Cut Line Indicator

- Fences and Material Supports

- Dust Extraction

- Additional Features and Accessories

- Miter Saw Safety Gear

More Miter Saw Content You Might Be Interested In

Which Type of Miter Saw Should You Buy?

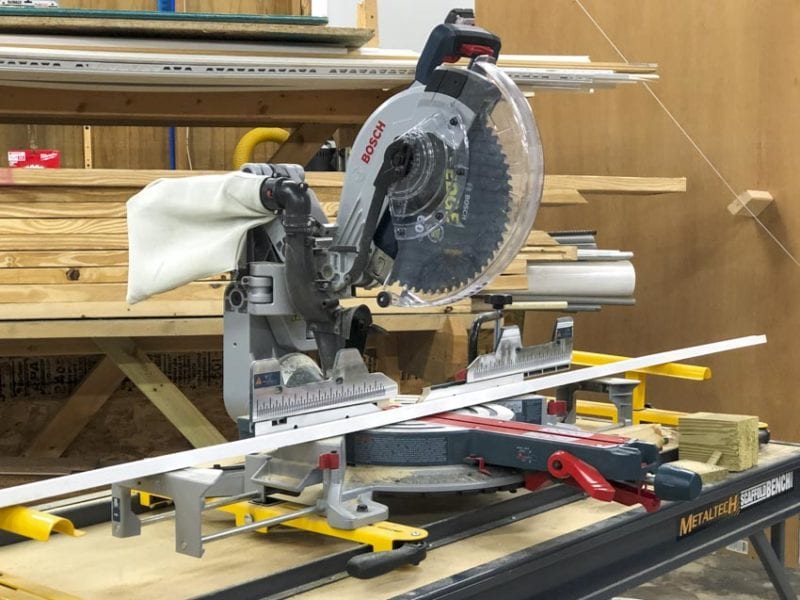

Before buying, make sure you understand the types of miter saws so you match your required features and capacity. Miter saws fall into three primary categories: stationary compound, sliding compound, and sliding dual compound (also called double or dual bevel). As you might guess, the price increases with a saw’s design sophistication.

Stationary compound miter saws can make miter cuts to the right and left, but bevels in only one direction.

Sliding compound miter saws add the capability of moving forward and back along rails.

The most versatile is the sliding dual compound miter saw that can do everything the other saws can do plus bevel to both the right and left.

The two sliding designs are the most popular because the rails increase a blade’s crosscut capacity. For example, picture a miter saw blade 12 inches in diameter. If the saw doesn’t slide, the maximum crosscut capacity for a 90° cut is the blade diameter—12 inches. (Well, less than 12 inches thanks to the arbor getting in the way.)

However, a sliding feature can increase the crosscut by several inches—up to 16 inches or so on the largest models. For compact miter saws, a sliding function can get you a crosscut capacity equal to or greater than a stationary 12-inch model.

Buying a Chop Saw vs Miter Saw

Now, you might be thinking that you’ve seen saws that resemble a miter saw but neither miter nor bevel. That was most likely a chop saw, and it’s important to understand the difference between chop saws vs miter saws. Even though many people call miter saws “chop saws,” they’re not the same thing.

You typically use chops saws with abrasive or diamond wheels for metal cutting. While there are a few multi-purpose saws out there, most are either dedicated to wood cutting or metal cutting.

Consider chop saws and miter saws as two separate tools. Most run at different speeds to match the materials they’re designed to cut. Chop saws are also sealed to withstand the hot metal waste produced during the cut.

Should You Buy a Battery-Powered or Corded Miter Saw?

Most miter saws are corded tools with 10-, 12-, or 15-amp motors. Compact sizes tend to have the smaller motors, while 10- and 12-inch models typically have 15-amp motors.

If you’ll be making a lot of wide crosscuts or cutting hardwoods, don’t skimp on power. If you’re cutting thinner trim made of pine or composite material, a less powerful motor is adequate.

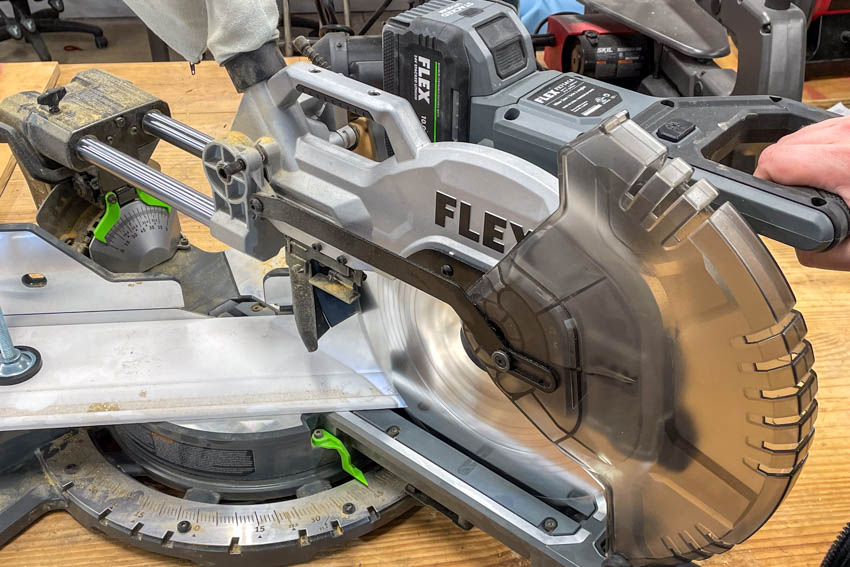

However, corded miter saws are no longer the only option. Viable battery-powered options with brushless motors like Bosch’s 18V ProFactor Axial Glide 12-inch Miter Saw or Makita’s 40V XGT 12-inch Miter Saw give tradesmen and serious woodworkers a reason to rejoice. There are even affordable DIY-focused models available with plenty of power for the job.

Additionally, today’s cordless miter saws are smaller, lighter, and exceedingly useful, even as the primary model for your crew.

What Size Miter Saw Should You Buy?

We talked briefly about the crosscut capacity already, but there’s more to be said (and I’ve never been short on words!). The most common miter saw sizes are 7 1/4, 8 1/4, 8 1/2, 10, and 12-inch, based on the diameter of the blade they use.

A larger blade diameter allows for greater cut capacity in both length and depth. As you consider what projects you’re going to work on, make sure the saw’s capacity exceeds that width. A quick look at the saw’s specifications will tell you what you need to know about 90° crosscut, 45° miter, and vertical cutting capacities.

One advantage of the 10-inch blade diameter is that you can use the same blade on a table saw. You won’t need to buy two sets of blades if you don’t mind taking the time to swap them between your table and miter saws.

The same holds true for your circular saw and compact miter saws that use 7 1/4-inch blades. The 7 1/4-inch blades are more readily available, which is a big advantage in a pinch.

What Miter Saw Blade Should You Buy?

The stock blade on a miter saw usually has a mid-range tooth count and is good for general-purpose cutting.

If you’re cutting hardwoods or want a finer finish for woodworking and high-end carpentry, go with a higher TPI (Teeth Per Inch) count. The higher the tooth count, the finer the finish. For a 12-inch miter saw, this would be a 60- or 80-tooth blade.

There are also specialty blades available. While you should never cut metal with a miter saw, you can cut engineered flooring, Hardie Board, and several other non-wood materials.

Pro Tip: High tooth count blades cost more than low tooth count, but the best can eliminate the need to sand the edges of your wood.

What Miter and Bevel Capacity Should You Look For?

There’s some variability in the maximum miter and bevel ranges, but all miter saws will be able to cut miters and bevels up to 45°.

You’re likely to find a more generous range when you’re cutting miters. It’s common to cut 50° to the left and 60° to the right, and we’ve even reviewed a model that mitered 70° in both directions.

For bevel capacity, 47° or 48° is the norm, and dual-bevel miter saws usually have the same capacity to both sides.

There are some tricks of the trade for cutting odd angles, but the details are beyond the scope of this article. With the exception of some odd angles for skilled carpenters, any miter saw will have the necessary angle ranges you need. Having bonus capacity or dual-bevel capacity reduces the math you have to do or makes cuts easier to accomplish.

Nearly every miter saw on the market has positive stop detents. A detent is a mechanical catch that locks a machine’s movement until you release or override it. Once you properly calibrate your miter saw, there’s no guesswork about accurate cuts on the most common angles.

Most saws have detents at 90°, 45°, and 22.5° at the least, while 15° and 31.6° are also common. Look for a saw with an easy, smooth detent override that allows you to move the saw without the detent engaging each positive stop along the way and back.

Saws will likely have fewer bevel detents (and some have none). It’s nice to have them at least at 0° and 45°, and it’s common to have them at 15°, 22.5°, 33.9° as well.

Pro Tip: More miter saws are moving to front-mounted bevel adjustments. They’re much more convenient than reaching around to the back.

Should You Get a Laser or LED Shadow Cut Line Indicator?

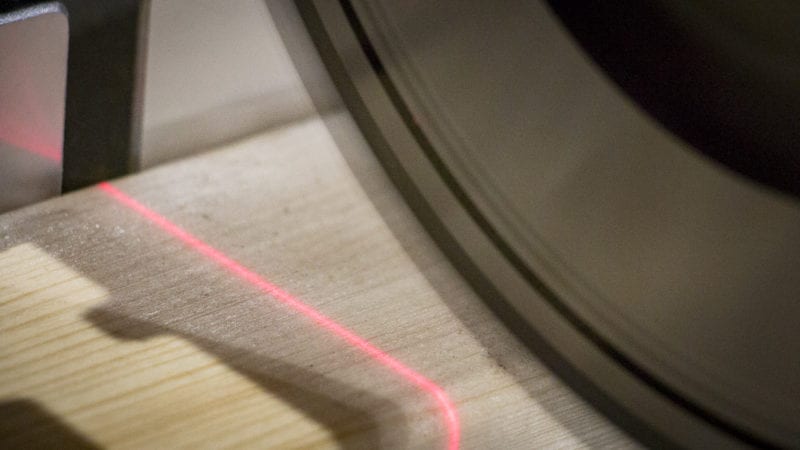

For years, miter saws have used a laser beam to mark the blade’s path across the material. It’s a premium feature, to be sure, so not every saw has it.

Although they work reasonably well, they certainly don’t make accurate cuts foolproof. First, the red laser diode isn’t tied to the blade, so it’s possible it can be off by a hair, and you have to remember to calibrate it from time to time. We’ve had saws that would leave our cuts 1/8-inch short if we didn’t know the last person to use it set the laser to cut to the right of the line.

Of course, the diode can also just malfunction and not shine. But perhaps the biggest drawback is the one we associate with red laser levels in bright light—they’re hard to see in direct sunlight. Since miter saws are often outdoor jobsite tools, sunlight reduces the laser’s usefulness.

So, is there a solution? Well, yes, and ironically, it’s a lot less sophisticated than a laser. Some miter saws now use an LED light to cast the blade’s shadow onto the material. Since the blade creates the shadow, it’s always accurate. Although the LED could go out (we’ve never had that happen, though), it’s easy to see a shadow even on the brightest of days.

Fences and Material Support Considerations

A miter saw’s fence provides an accurate anchor point to secure material during the cut. Always be sure to firmly press your material up against the fence. Failure to do so is dangerous since the saw blade can grab the material and violently jerk it toward the fence. We’ve seen inexperienced users send smaller stock flying and splintering by not using the fence properly.

Fences come in different heights, and some even slide out to extend support for longer pieces. If you plan to cut tall crown molding or other tall stock, opt for taller fences for maximum support.

Speaking of support, material support extensions on either side of the table are helpful for flimsy or longer material. However, they’re not as effective as the extension supports found on devices like the Milwaukee folding miter saw stand, which we’ll discuss in a moment.

Did I mention that the stock should always be firmly against the fence?

What Dust Extraction Features Should You Look For?

Every miter saw should have a dust port and come with a dust collection bag. The bag is moderately effective, catching up to 90% of the dust you create in the best cases. Connecting a vacuum is significantly more effective, though.

You’ll rarely—if ever—see a dust extractor (vacuum) attached to a miter saw during the framing process. Rough cuts are often made outside, throwing debris out of the dust chute and into the dirt. It’s not particularly neat and tidy, but it doesn’t need to be.

When you’re making miter saw cuts in your shop, garage, or a customer’s home, a good shop vacuum is a must to contain the mess and reduce how much cleanup you need to do at the end of the day. Since sawdust is relatively lightweight, a vacuum with high CFM is more important than high water lift.

It’s not just for the mess, though, it’s also for the safety of anyone who breathes the air. Besides being immediately unpleasant, inhaled particles are hazardous to your lungs over time.

What Additional Features and Accessories Should You Look For?

We prefer miter saws with a soft start motor. By spinning up with a slower acceleration, you get quieter, smoother operation, with less of a jump when you pull the trigger.

A saw with a blade brake is helpful as well. A brake electronically stops the blade within a few seconds of you releasing the trigger. Without a brake, the blade can continue to spin for 15, 20, or even thirty seconds, extending your risk of injury or damage to your material. Most miter saw on the market today have a blade brake.

Any miter saw you’re considering needs an arm lock that immobilizes the up-and-down action of the blade and nests it in the table’s blade channel. The arm lock makes the saw a little more compact and safe when it’s not in use and makes it easier to transport. Any portable miter saw you buy should have this feature.

A handle on the top of the saw makes it a little easier to move around. Compact saws are the lightest and easiest to carry, but even full-size saws have carry handles. With a weight of 60+ pounds, you might want to invest in a good rolling miter saw stand for 10- and 12-inch models, though.

Most miter saws come with a material clamp. Once you have your material set against the fence and lined up for the cut, the clamp acts as your third hand so you can manage the waste end of your cut with one hand and operate the saw with the other.

The handiest accessory for a miter saw is a stand. Not only does it hold the saw securely which limits vibration, but it has extendable material supports for cutting long stock. Some even have material stops which eliminate the need to mark multiple boards for the same cut—just set the stop and cut. We recommend springing for the miter saw stand if you’re not locking it down to a workbench.

Pro Tip: The best miter saws stands include gravity-rise stands which roll easily and setup quickly.

What Miter Saw Safety Gear Should You Buy?

Miter saws can be dangerous tools, so what safety gear should you use?

Safety glasses are a must. Even a single piece of wood flying toward your eye can mess up your life and contribute to your eye surgeon’s Porsche fund. Wear them every time you cut—no excuses.

Ear protection can be helpful as well. Even though miter saw cuts aren’t usually long-duration, they can be loud, and you can’t reverse tinnitus, so better safe than sorry.

What about gloves? Absolutely NOT! If any part of the glove accidentally touches that spinning blade, it will get caught up and pull your hand in, resulting in gruesome injuries that happen in a split second.

Why You Can Trust Pro Tool Reviews

Ever check out a “review” site and you can’t tell if they actually tested the tools or if they’re just “recommending” the Amazon top sellers? That’s not us. We won’t recommend anything unless we’d actually use it ourselves and we don’t really care who the primary retailer is. It’s all about giving you a legitimate recommendation and our honest opinion of each product.

We’ve been in business since 2008 covering tools, writing reviews, and reporting on industry news in the construction, automotive, and lawn care industries. Our Pro reviewers work in the trades and have the skills and experience to know whether tools can perform well in the field.

Each year, we bring in and review more than 250 individual products. Our team will put our hands on hundreds of additional tools at media events and trade shows throughout the year.

We consult with innovators in the technology and design of tools to gain a broader grasp of where these products fit and how they work.

We work with more than two dozen professional contractors around the United States who review products for us on real job sites and consult with us on testing methods, categories, and weighting.

We’ll provide more than 500 pieces of new content this year, absolutely free for our readers—including objective evaluations of individual tools and products.

The end result is information you can trust because of the editorial, scientific, and real-world professional experience we collectively utilize each and every time we pick up and test a tool.